Continuous Inkjet Printers (CIJ)

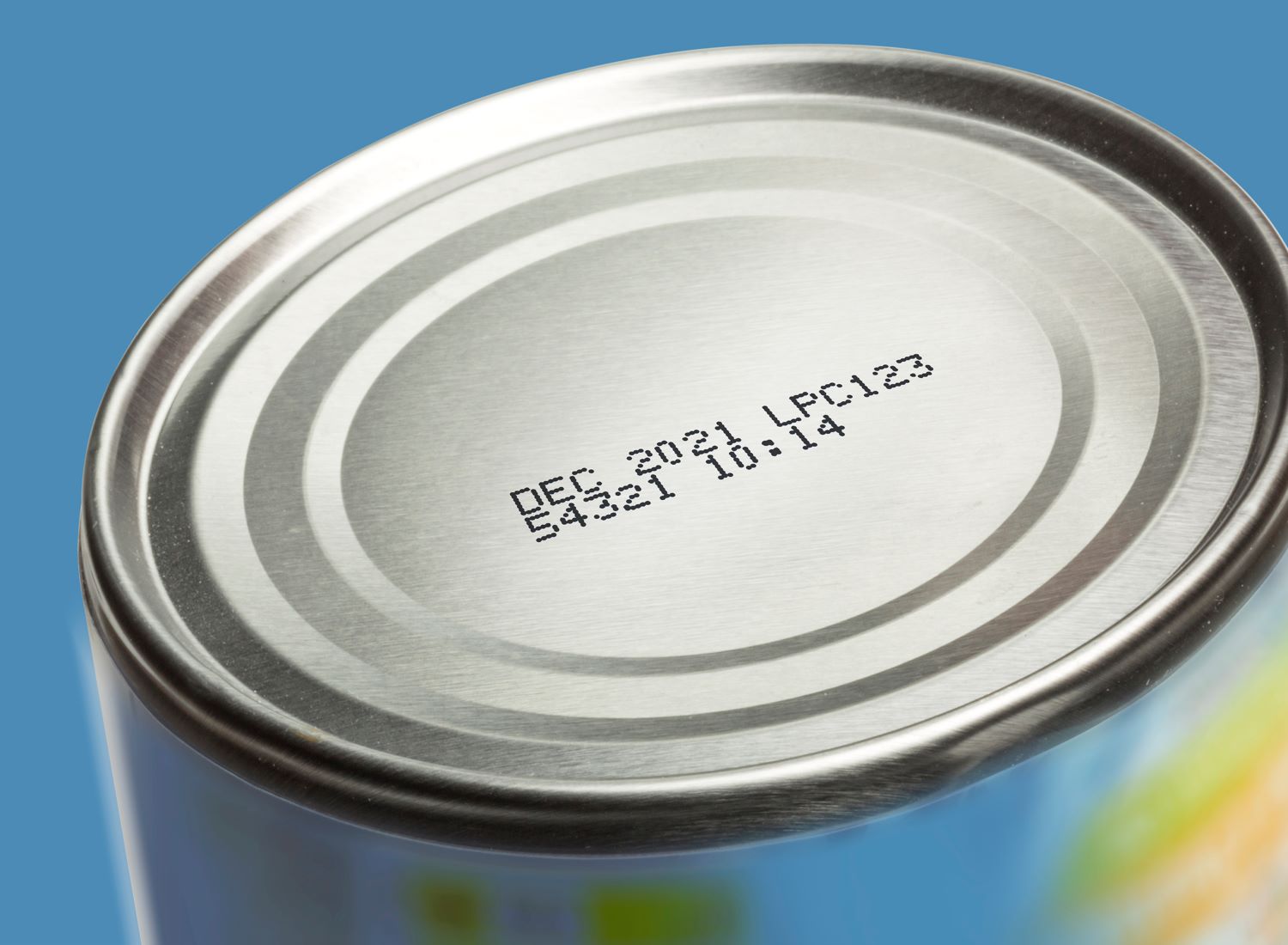

Continuous ink jet printers are used to print variable information, such as dates or batch codes, on individual products as they move along the production line – regardless of porosity, size, shape or texture.

PrinterNet, remote CIJ printer monitoring and support, enables customers to access and control Linx coders anywhere, anytime and enables Linx to provide remote support to keep lines running.

With concealed, easy-to-clean printheads, error-free touch-screen control and simple self-service capability, Linx Printing Technologies provide a cost-effective and efficient solution compared to similar industrial inkjet printers on the market.

Why Employ Continuous Inkjet Printers?

Continuous inkjet coders are perfectly suited for printing a wide range of information onto products and packaging on production lines. They are designed for automatic printing of batch codes, dates, barcodes, number sequences, general text, and even brand & product names.

Manufacturers and packing operations often use them for reliable traceability and in specific industries, compliance with legislative requirements. Linx continuous inkjet printers are renowned worldwide for ease of use, reliability, low running costs and the ability to mark materials of nearly any texture, shape, size or porosity.

How does a continuous inkjet work?

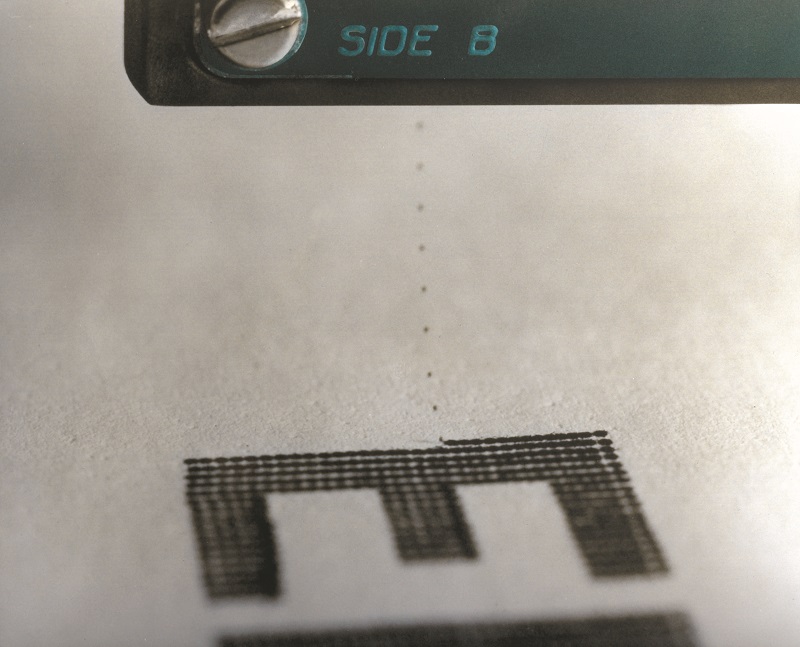

The continuous inkjet printing process works by expelling electrically charged ink droplets from a printhead nozzle and passing them through an electric field.

The ink jet is broken into drops inside the chamber through a pulse from the piezoelectric crystal. Droplets that are required for printing are charged by an electrode as they break off from the ink jet, and the printer re-circulates the rest.

The droplets, now charged, pass through an electrostatic field between deflector plates, a combination of speed and charge determines the correct position of the droplet on the substrate.

Up to 80,000 of these tiny droplets – half the diameter of a human hair – are expelled every second, and this is done without contact to the material being printed on.

Our CIJ Printer Range

Linx 8900 Series

Increasing operational efficiency, made easier than ever with remote connectivity to keep you in control, anytime, anywhere

Applications & Materials

24/7 operations | Barcodes | Batch coding | Data Matrix and QR codes | High-speed production | Retail packaging | Print up to 6 lines

Key Benefits:

- Remote access, control and support with Linx PrinterNet

- Designed to support error-free coding

- Quick operation with simple touch screen interface

- Primary and secondary packaging with one printer

Linx 8940 Spectrum

Designed to make high-contrast pigmented ink printing easy.

Innovative self-service Vortex® system and PureFlow® filter increases production uptime, extends maintenance intervals and ensures a cleaner printhead. The IP65 rated Linx 8940 Spectrum delivers a stronger contrast print and faster print speeds of up to 10 m/s.

Less cleaning, more coding.

Linx 10

Simple CIJ printer – superior to other

entry-level coders, with remote connectivity to keep you in control, anywhere, anytime

Applications & Materials

Any dry substrate | Best-before dates | Batch coding | Slow-medium speed production | Print up to 3 lines

Key Benefits:

- Remote access, control and support with Linx PrinterNet

- Simple to use

- Quick and easy to set up

- Lightest, most compact CIJ printer in its class

- Low running costs

- Robust construction

Linx 7900 Series

Specialist CIJ coding solution with low

cost of ownership, with remote connectivity to keep you in control, anywhere, anytime

Applications & Materials

Any dry substrate | Barcodes | Batch coding | Cartons | Data Matrix 2D codes | Advanced production | Print up to 5 lines

Key Benefits:

- Automatic printhead cleaning system ensures trouble-free start

- Automatic code setup for faster, error-free coding

Error free printing, self-cleaning printhead, error-free touch screen, printing on various materials and able to print wide range of information such as barcodes, dates and logos are only some of the advantages to a CIJ printer. To find out more, click here.

They both work well for different applications. Continuous inkjets (CIJ) are perfect for printing wide range of information onto a product and packaging, able to print batch codes, dates, and barcodes. Lasers however are ideal for high print volumes such as the pharmaceutical and beverage industry. It offers permanent traceability making it ideal for the automobile manufacturing.

CIJ printers have a small footprint, meaning they can be easily moved from production line line A to B. To better the manoeuvre, trollies can be purchased with the equipment.

We offer a variety of inks from black ink, yellow, red. We offer odour free, grease proof and so much more. Get in contact with us here and one of our specialist will be happy to assist further.

Explore More Linx Printing Technologies

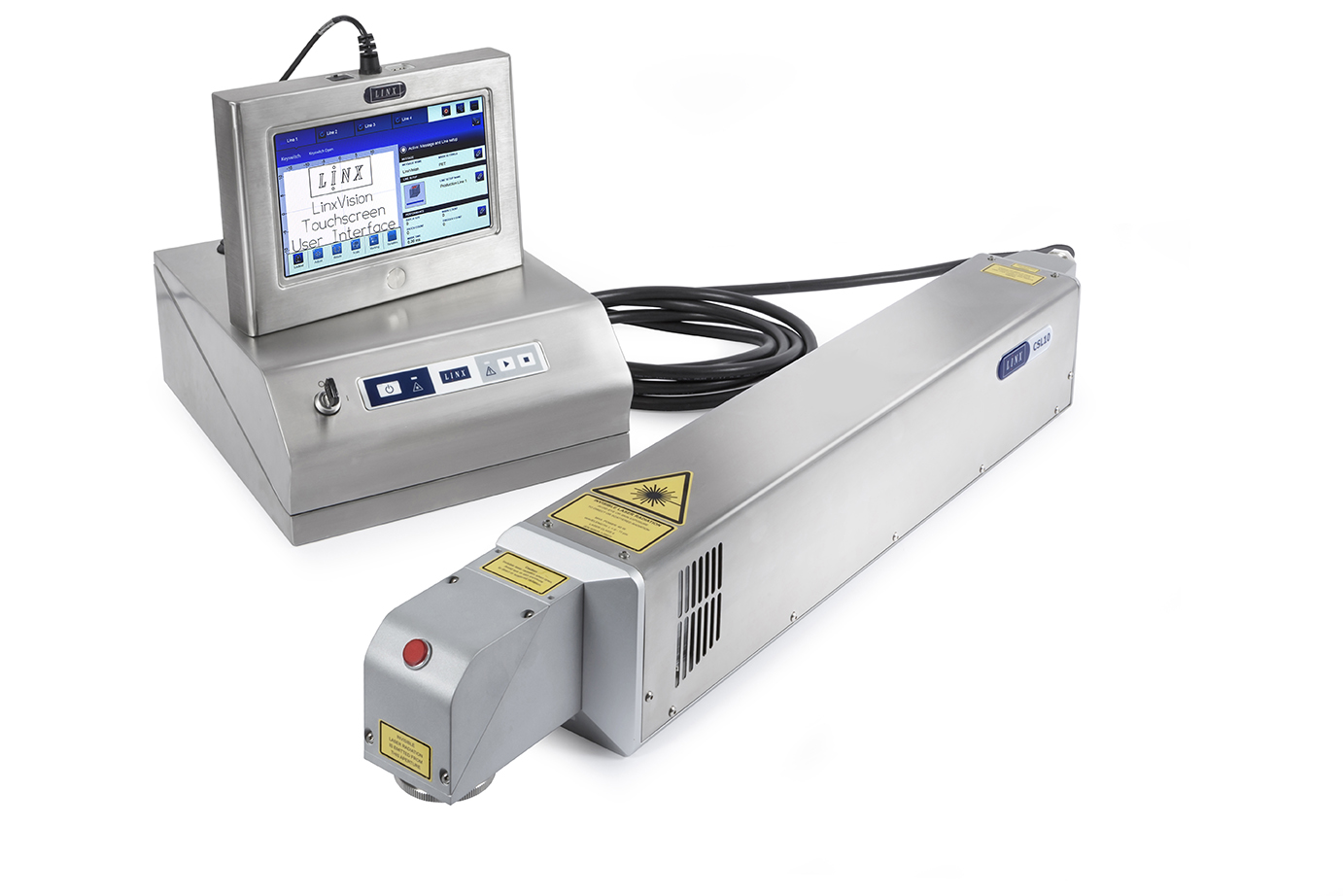

Compare Linx Laser Jet Printers

Laser coding and marking solutions for a range of materials and environments

Inkjet Coding Applications

Our products are used by manufacturers worldwide, browse by industry or substrate.

Remote Printer Management

Mobile monitoring and remote control of your Linx production line printers.