Meat Industry Coding, Marking & Packaging

For meat processors, abattoirs and manufacturing plants, the right coding and marking equipment can play a significant part in ensuring readiness for the opportunities ahead in the food industry. As such, the meat sector demands code accuracy & legibility, reliable traceability, and dependable coding equipment which will satisfy regulations and maximise uptime even in challenging production environments.

Linx printers integrate easily into awkward and confined spaces. With protected IP55 and IP65 rated enclosures, they are tailored to resist contamination and water ingress on food manufacturing lines. Additionally, with easy-to-clean printheads, intuitive touch controls and self-service capability, our coding and marking solutions are perfectly adapted to a full range of food manufacturer requirements (including printing onto labels, packaging and onto food products themselves).

Benefits of Linx meat marking solutions:

- Designed to cope in challenging manufacturing settings with sealed printheads

- Utilize right-angle printheads, enabling use within awkward production lines

- Deliver legible and durable codes able to meet labelling and FSA regulations

- Compatibility with a huge range of materials and substrates in the food industry

- Remain cost-effective with minimal intervention and maintenance required

- Specialist machines offering reliable print quality, even at high output speeds

Meat Marking Capabilities

For this sector, a range of powerful Linx products are ideally suited to the coding of

meat products and related packing.

Compatible materials:

- Flexible & rigid packaging

- Plastic, PVC, PET, bags & films

- Recycled packaging

- Packaging with additives

- Rubber

- Glass

- Cardboard

- Metals

Linx capabilities include:

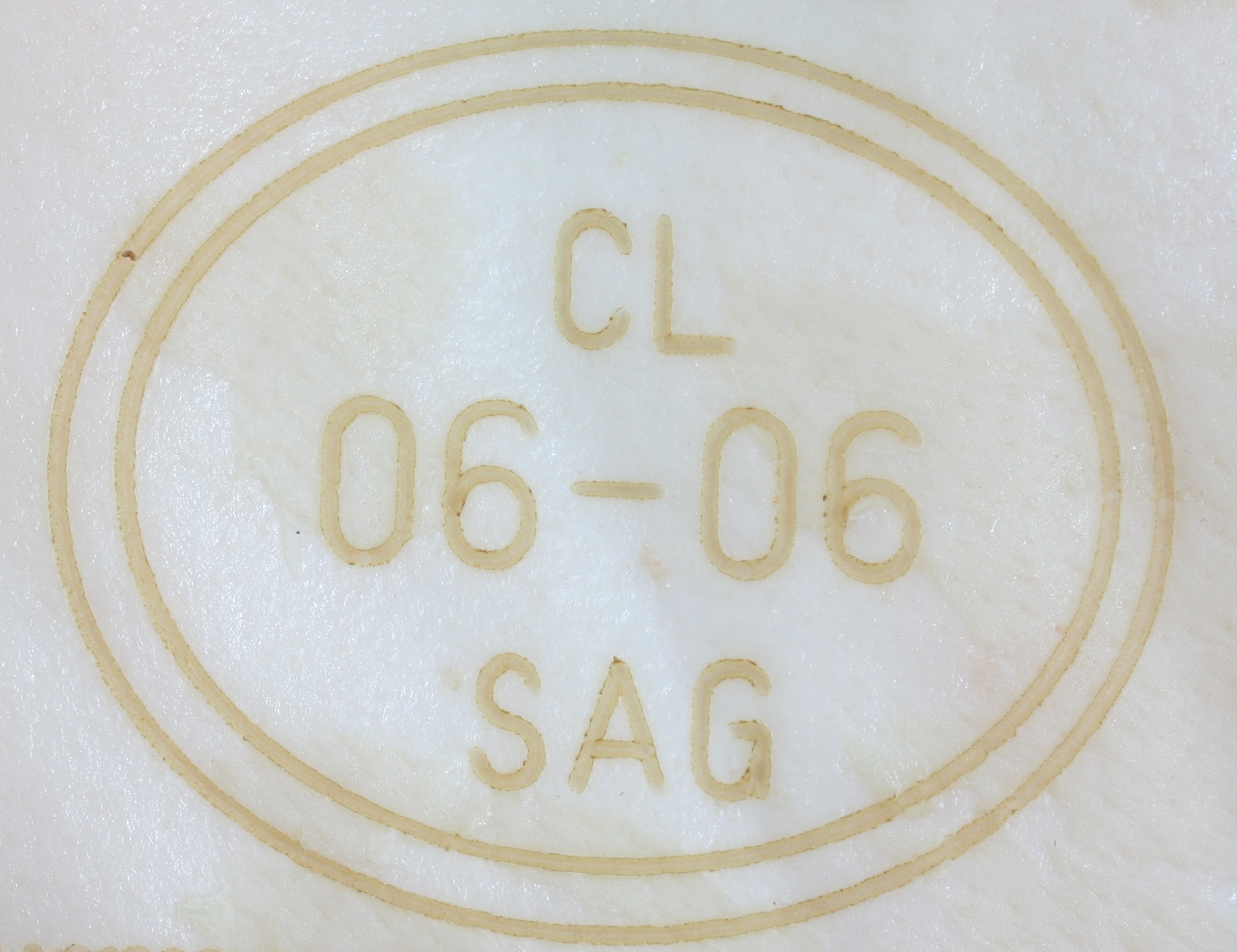

- Best before dates

- Batch coding & barcodes

- Traceability

- Logos, characters, text & complex 2D codes

- Specialist & food-grade ink printing

- Printing directly on food (e.g. meat, egg shells)

…and more. Contact us now for further information.

Meat Marking Solutions

Continuous Inkjet (CIJ) Printers: non-contact printing with a huge range of process-specific inks, cost-effective and perfect for flexible sleeves or boxes of plastic, card and more.

Laser Coding Machines: for permanent coding at high speeds, lasers will mark many substrates (including directly coding on meat) with no added consumable cost.

Large Character Printers: also known as ‘case coders’, particular adapted to printing text and graphics on secondary packaging, supporting a range of materials and substrates.

Not sure which product is best for your meat coding requirements?

Industries

Linx offers a range of options for date and batch coding, data matrix and 2D code capability, product marking and much more. Consequently, our coding and marking equipment is used within the following industries and beyond:

Food | Packaging | Dairy | Fish | Ready Meals

Related Information

IP65 rated, offering high-speed and quality coding, the Linx SLHP is an ideal solution for meat processing environments.

Learn how Quality Foods of Aberdeen utilised the Linx IJ355 case coder as a cost-effective and reliable part of their production.

Many Linx inks are suited for meat processing, including food grade, odour-free, grease-penetrating, USDA compliant inks, and more

Resources

Special Adherence Inks Datasheet

Quality Foods

Nythe Farm Kitchen Case Study

Batch Printing Solutions For The Meat Industry White Pape

Coding Systems for Lean Production White Paper