Laser Marking for Metal Parts

In the world of industrial printing, the need for efficient and reliable marking technologies for metal parts and substrates is paramount. The ability to accurately and permanently mark metal components is crucial for traceability, product identification, and overall quality control. Among the various printing technologies available, industrial laser coders and markers have emerged as the most suitable option for metal materials, though there are also benefits to employing CIJ printing technology. In this article, we will explore the reasons why laser technology may be the most appropriate for metal parts, examine real-world use cases, and discuss instances where alternative technologies may be preferred.

Advantages of Laser Technology for Metal Parts

Permanent and Durable Markings

Laser coders and markers provide permanent and highly durable markings on metal. The laser beam interacts with the surface of the metal, creating a lasting bond that withstands harsh environmental conditions, including extreme temperatures, chemicals, and abrasion. This longevity is crucial for applications where long-term traceability is necessary, such as in automotive or aerospace part marking.

High Precision and Resolution

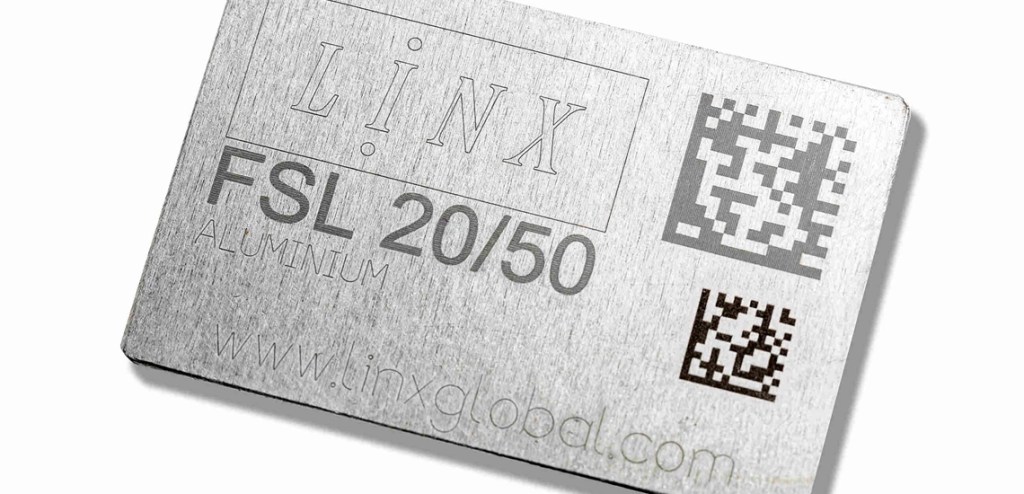

Laser technology offers exceptional precision and resolution, enabling the production of detailed markings on metal surfaces. The focused laser beam ensures that even the smallest characters, intricate designs, and barcodes can be accurately etched onto metal parts. This level of precision is especially crucial in industries where product identification and readability are of utmost importance, such as aerospace and medical devices.

Non-Contact

Laser coders and markers are non-contact, meaning they do not physically touch the surface of the metal parts during the marking process. This attribute is particularly advantageous for certain applications where the product could be damaged by direct contact. However, the process does burn/etch the surface and is therefore inherently destructive (on a small scale) so this will need to be taken into account depending on the particular substrate.

Wide Compatibility with Metals

Laser technology exhibits excellent compatibility with a wide range of metals, including stainless steel, aluminium, titanium, brass, and more. Unlike some alternative printing technologies, lasers can effectively mark various metal alloys, allowing for versatility in industrial applications. Whether the metal surface is polished, coated, or rough, laser coders and markers can produce high-quality markings consistently.

There are considerations to take into account when utilising laser technology in conjunction with metal parts. For example, remaining complaint of IEC and FDA standards when using lasers is important. Some of these standards are particularly critical when marking on metal such as the enclosing of the laser head with an adequately reflective shield for both light and heat in order to prevent the laser from unwanted reflection of the metal surface.

Real-World Use Cases: Automotive Part Marking

The automotive industry relies heavily on efficient part marking techniques to ensure product traceability, improve manufacturing processes, and to meet regulatory requirements. Laser technology has found extensive utilisation in automotive part marking due to its unique advantages:

VIN Marking

Laser coders and markers are widely used to engrave Vehicle Identification Numbers (VINs) onto metal parts. The high precision and durability of laser markings ensure that vital information remains intact throughout the vehicle’s lifespan, aiding in identification, recall management, and anti-counterfeiting efforts.

Component Marking

Laser enables the direct marking of various automotive components, such as engine blocks, chassis parts, and brake components. These markings include part numbers, batch codes, logos, and serial numbers, facilitating part tracking, inventory management, and quality control.

Compliance with Industry Standards

Laser coders and markers offer the necessary flexibility to meet automotive industry standards for part marking. Whether it’s complying with specific regulations like the UK’s Transport Act and Department of Transport’s requirements or adhering to international standards, laser technology allows for precise, standardised, and easily readable markings.

Considerations for Alternative Technologies

While laser coders and markers excel in most metal part marking applications, there are instances where alternative technologies, such as Continuous Inkjet (CIJ) printers, may be considered.

In certain industries, such as beverage manufacturing, marking on metal cans presents unique challenges. CIJ printers have traditionally been favoured for their ability to code on curved and uneven surfaces, like aluminium cans, due to their ability to adapt to varying surface heights and contours. However, laser technology has made significant advancements and can now achieve reliable and high-quality can coding, providing an alternative solution. In addition, whilst CIJ uses ink to mark products, lasers vaporise the material or actually change the material through heat. As such, laser technology creates a more permanent code than CIJ technology.

Laser technology typically requires a higher initial investment compared to some alternative printing technologies. In cases where cost constraints are significant factors, CIJ printers may be considered as a more cost-effective option for basic metal part marking applications, as long as the specific requirements for permanence and precision can be met.

Industrial laser coders and markers have emerged as a highly suitable printing technology for metal parts and substrates. Their permanence, precision, compatibility with metals, and wide range of real-world applications, particularly in automotive part marking, make them indispensable tools for industries requiring durable and highly readable markings. While alternative technologies like CIJ printers may have their niche applications, the continuous advancements in laser technology have expanded their capabilities, making them the preferred choice for most metal marking needs. As industries continue to evolve, laser coders and markers will undoubtedly play a crucial role in ensuring traceability, product quality, and compliance within the realm of metal part marking.