Micromix Plant Health

Micromix Plant Health in Nottingham is benefitting from flexible, reliable and quality coding, thanks to Linx 8900 CIJ printers.

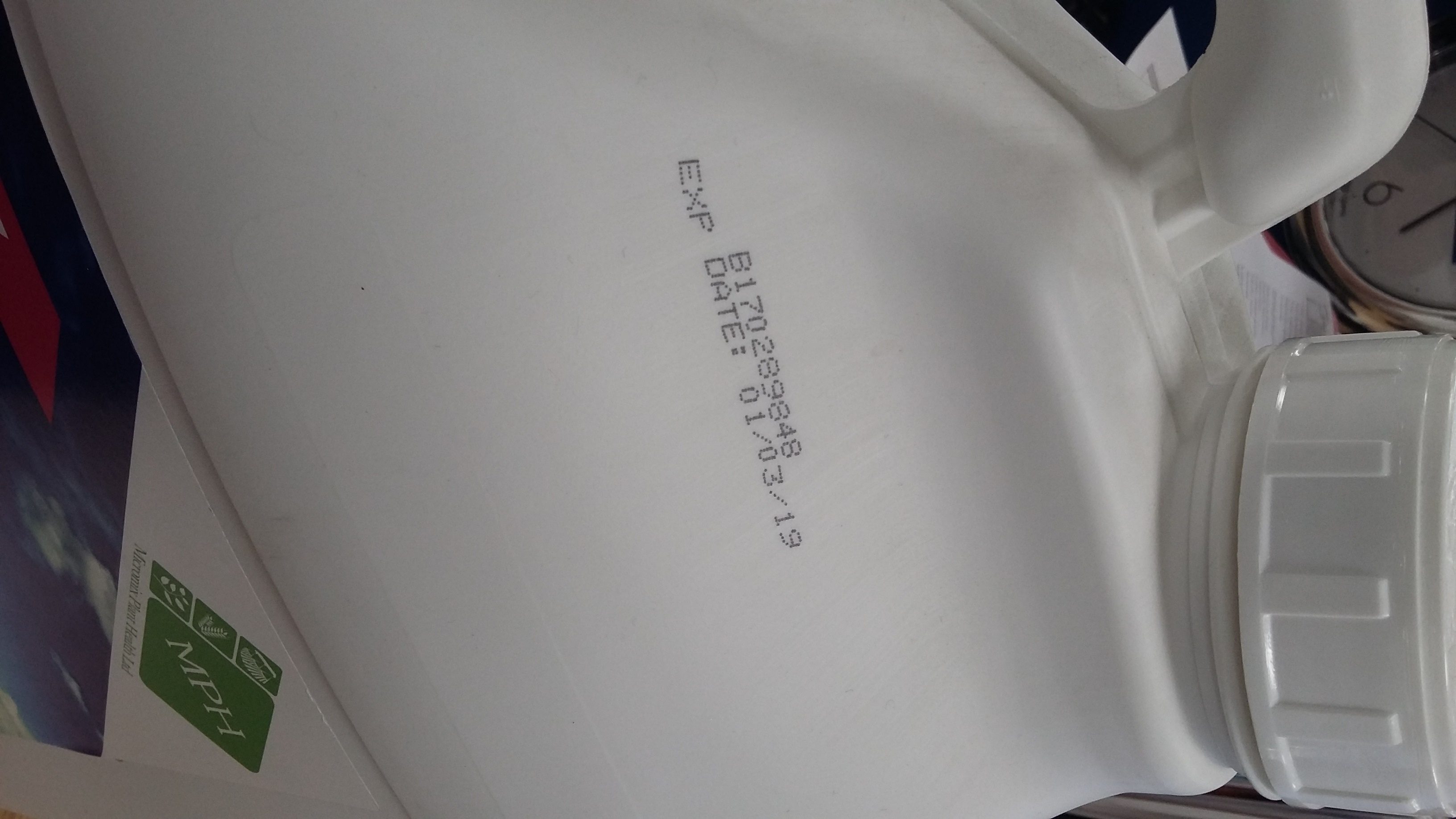

Micromix manufactures crop and plant nutrition products, and also offers a contract packing operation. Therefore the company has a range of coding requirements for different pack formats, including bottles, buckets and boxes. The Linx 8900 printers replaced an alternative CIJ coder which had proved unreliable and messy to operate. In addition, hand applied labels were also inflexible, offered a limited area for coding and were liable to be removed. Regulations for packaging certain herbicides and pesticides require batch and traceability codes to be long-lasting. In addition, Micromix were seeing demands from customers for enhanced product branding through better quality codes.

The Linx 8900 provides crisp and durable prints across single, two and three line codes in line with Micromix’s different requirements. The printer also has the capability to code in any orientation, for example on the neck of a bottle, on the side or underneath, and it can be moved easily around the factory with changing production requirements.

The printer codes onto both plastic (HDPE and PET) and cardboard. For some products, the Linx 8900 prints the same code onto bottles and the cardboard box into which the bottles are packed.

The Linx 8900’s IP55 rating, together with Linx’s industry-leading sealed printhead combine to provide Micromix with a reliable printer which can operate in even the harshest factory conditions. This is particularly important for some of the company’s operations which involve packing cement powder.

“Our operators really like the 8900s,” comments Micromix’s Works Manager Chris Hardy. “They are easy to programme, and print every time without fail, so the bottles are going through more quickly and smoothly, and the printing is a lot neater and more readable than our old batch printers.”