Pharma manufacturer increases vaccine throughput with Linx lasers

Pharmaceutical manufacturer upgrades their laser coders from 30W to 60W to increase the throughput to meet production demand for COVID-19 vaccine

A major manufacturer of pharmaceuticals in Belgium produces medicines and now COVID-19 vaccines on high-speed lines. Linx distributor, Mundi Technology, has supplied this customer for over 20 years, so when they needed to upgrade their laser coders to increase throughput to meet demand the customer did not hesitate to contact Mundi to upgrade their Linx lasers.

Mundi’s extensive knowledge of laser systems and their good relationship with the customer’s checkweigher supplier meant that the customer felt confident that Mundi had specified the right systems.

The customer need

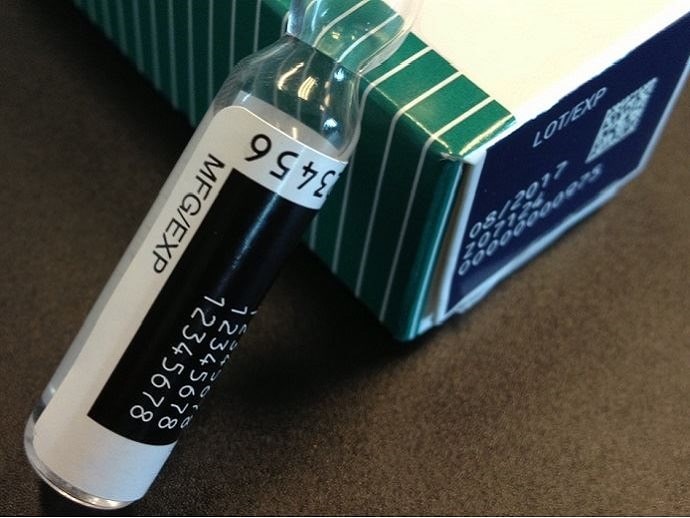

The customer codes four lines of human readable code onto paper labels which are then applied to ampoules running at a rate of 400 items per minute. The laser codes whilst the line is static, and the static coding time is 90ms. The lines run two shifts a day, five days a week.

On another line the customer codes four lines of human readable code plus a data matrix code onto carton boxes. The production line speed is 40 metres per minute and 250 cartons are coded every minute. The lines run for two shifts a day, for five days a week.

The integration of the laser coder with the customer’s checkweigher and data matrix scanner was essential.

The Linx solution

The Linx CSL60 laser coder is a 60W, CO2 scribing laser coder that offers reliable coding for faster and more demanding operations enabling the customer to increase capacity.

The flexibility of the coder means that the customer can have the right combination of tube and lens for their application.

This level of tailoring means that the laser tube is always running at an optimum rate, which extends the laser tube life beyond other suppliers, and also extends the time between service intervals.

As a result, the customer will enjoy less downtime and a lower cost of ownership.