Printing on Glass

Marking solutions have high importance in a wide range of industries, including those that require printing on glass products. Although each industry and company have their own unique challenges, there are still many qualities that are common.

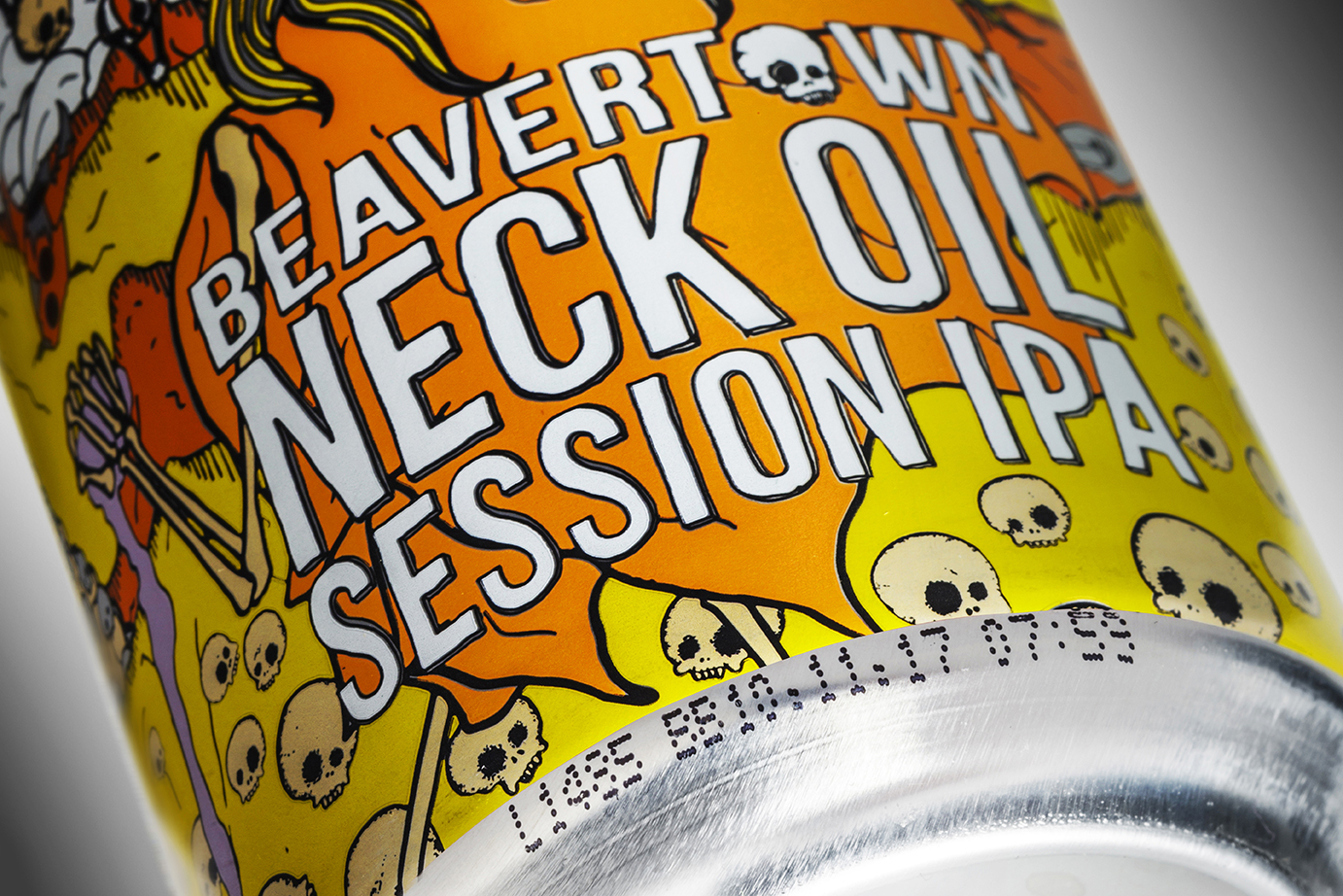

Glass part marking is used for identification and traceability. At Linx, we offer a range of printing technologies for coding and marking on both wet and dry glass. Whether you require an indelible identification code or one that can be removed before re-use, Linx has the product identification glass marking solution for you.

Benefits of Glass Printing

- Digital printing offers a considerable cost advantage over analogue. Low set-up requirements allow short production runs making a production line economical.

- Inks used for glass printing often require flushing and recirculation after use, to prevent sedimentation and print head blocking. Linx has specialised inks for certain applications making them work for different industries and preventing downtime. Our CIJ machines are built with an auto-cleaning system for the print head, minimising the mess and downtime.

- Linx printers are easily integrable into your production line, coding and marking at variable speeds. Our machines are also able to mark flat and curved surfaces without direct contact which is a unique advantage.

Printer Types for Glass Marking

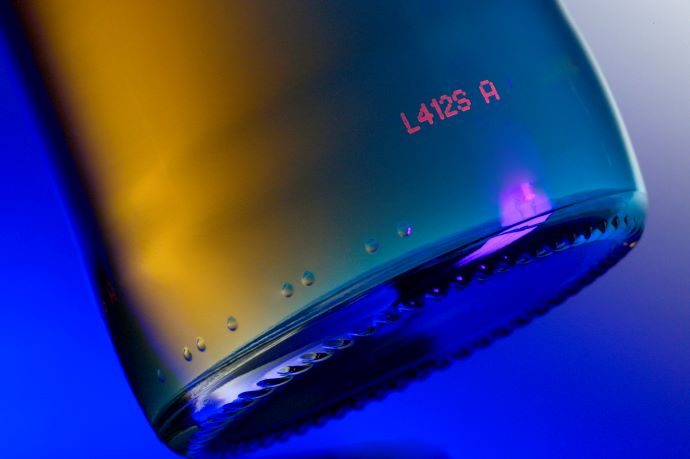

For internal traceability and anti-counterfeiting of high-value goods, our Linx UV readable inks for Linx Continuous Ink Jet (CIJ) printers provide a reliable printing solution for glass marking.

Linx CIJ printers reduce ongoing costs by efficiently using inks and solvents and are designed to be durable and reliable, meeting the highest standards of coding quality.

- Range of inks for specialist marking, e.g. food grade, invisible/UV coding

- Durable, high-quality multi-line coding

- Wide range of inks to keep your codes in place on nearly any substrate

- Optional IP protection for harsh environments

- Enables recycling of the glass after use

Our range of laser coders includes models for permanent coding and marking of both hot and cold glass, and includes robust models designed to operate in the extreme conditions of glass manufacturing plants.

Laser printers are ideal for permanent coding and provide a low operating cost product marking solution. Linx laser coding machines are designed for use in challenging, high-speed production environments while ensuring industry-leading text and code quality.

- Permanent marking capability

- Low operating costs – no need for consumables

- High-quality coding even on the fast line speeds

- Ideal for primary packaging coding and marking

- Permanent laser marking suitable for luxury goods and anti-counterfeiting product identification

Request a Print Sample

See what your glass code will look like.

To find out more information and to request your samples with no obligation, click the button below.

Ink Types for Printing onto Glass

Crucial to the performance and operation of our technologies, we recommend you only use Linx-approved inks and fluids in your Linx Continuous Inkjet, thermal Inkjet or Large Character coding equipment for printing on glass

Security (UV Readable) Inks

Inks which are near invisible in normal light but fluoresce violet or red under UV light. Suitable for anti-counterfeiting and other discreet coding applications.

Linx General Purpose Black Inks

Our range of general-purpose black inks gives outstanding performance on most common materials, ideal for most general external packaging applications.

How to Order

Linx inks and fluids are developed and produced to the highest quality standards. For more information and details of how to order consumables:

Working with Linx

Why not speak to one of our sales team about your particular needs in metal marking?

Contact us today, tell us about your product, manufacturing environment and your needs, and we will be able to provide you with the solution tailored to you. We will conduct a site survey and give you a no-obligation quote. Plus, you will get expert advice on installation requirements and help with managing your project.

Related Industries

Construction

Coding and marking solutions for the construction industry since 1987.

Resources

Wolds Manufacturing Case Study

Decantae Mineral Water Case Study

Top Ten Tips for chosing the right coder

Articles Related to Glass Marking

Introducing Our New Returnable Bottle Ink

In the current packaging and the environment debate, plastic is one of the biggest talking points.

Coding in a Wet Environment

All coders should be reliable, easy to use, and apply high-quality batch and date codes onto a range of products – but each sector has its own specific requirements.

No Quality Coder for Alcoholic Drinks

We get it: as a drinks producer, coding and marking is not always at the forefront of your mind.

Yes, we do. All we need to collect is some information regarding the production process and leave the rest to us! Get in contact with us here to get your samples.

Yes – we have full installation and operation manuals. Please contact us here for the desired manuals.

In the event of a loan system being available, this can be handled. Please contact us here for more information

Yes – Linx holds a valid ISO9001 Quality Certificate.