Coding and Marking on Electronics

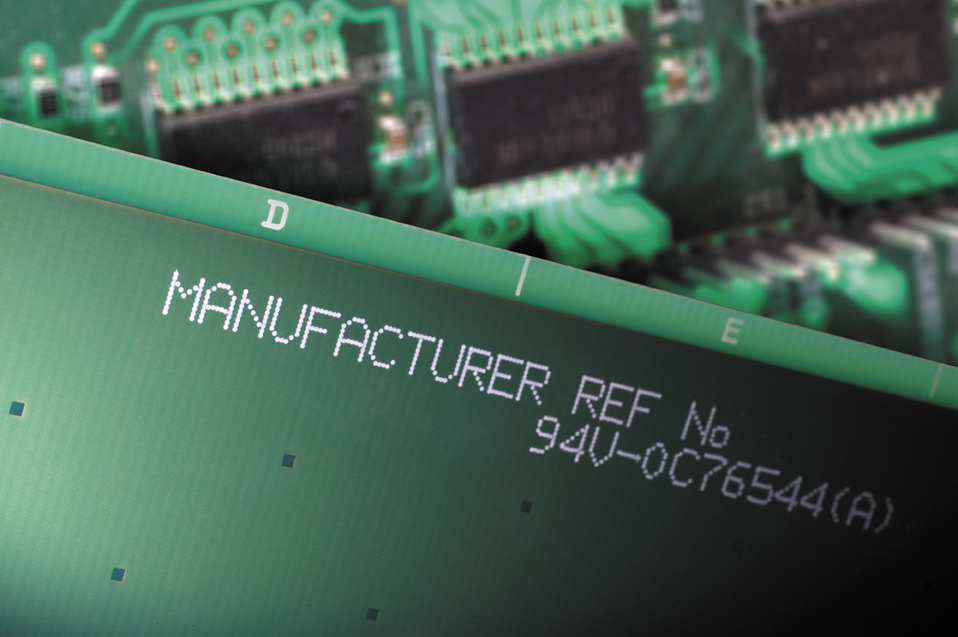

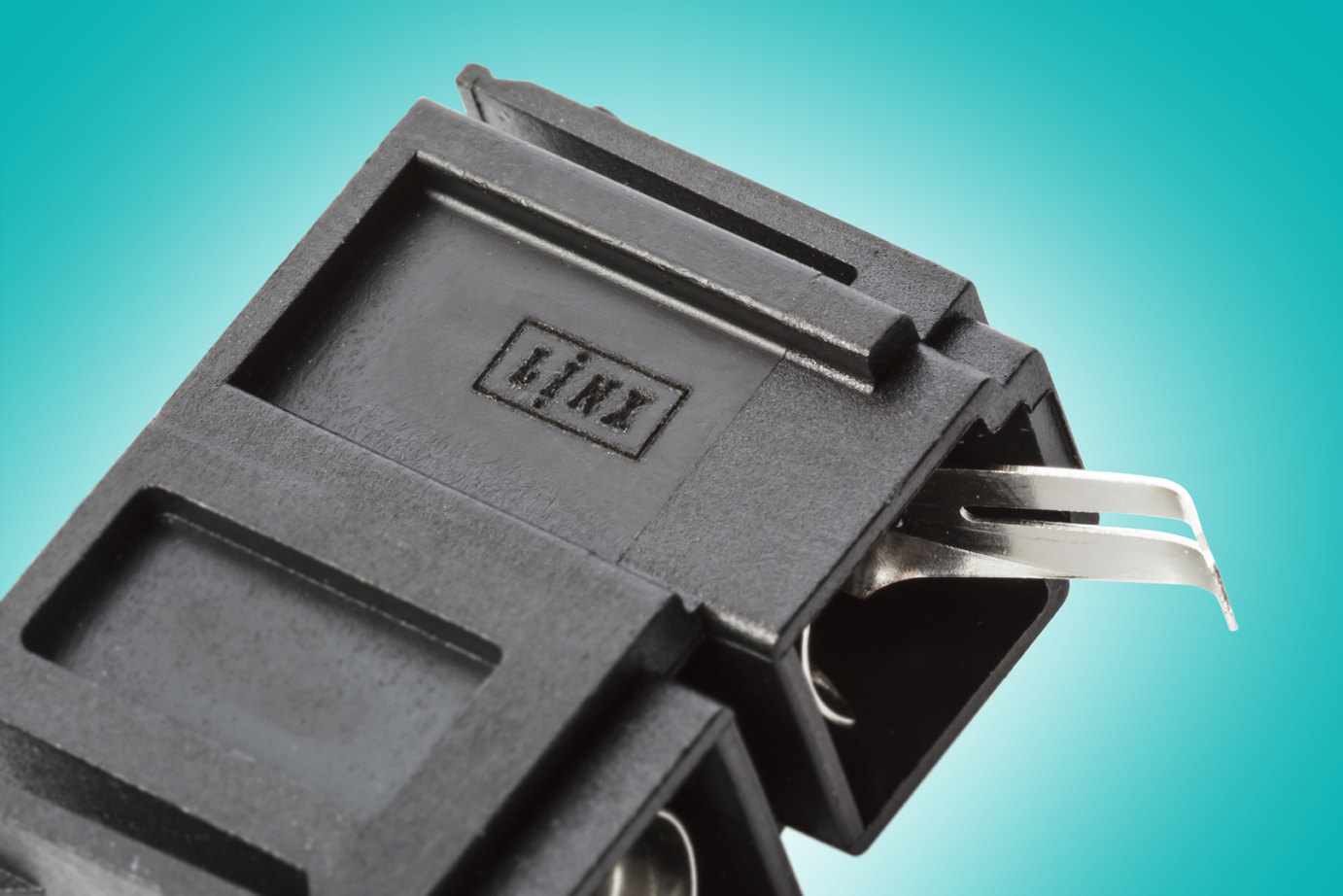

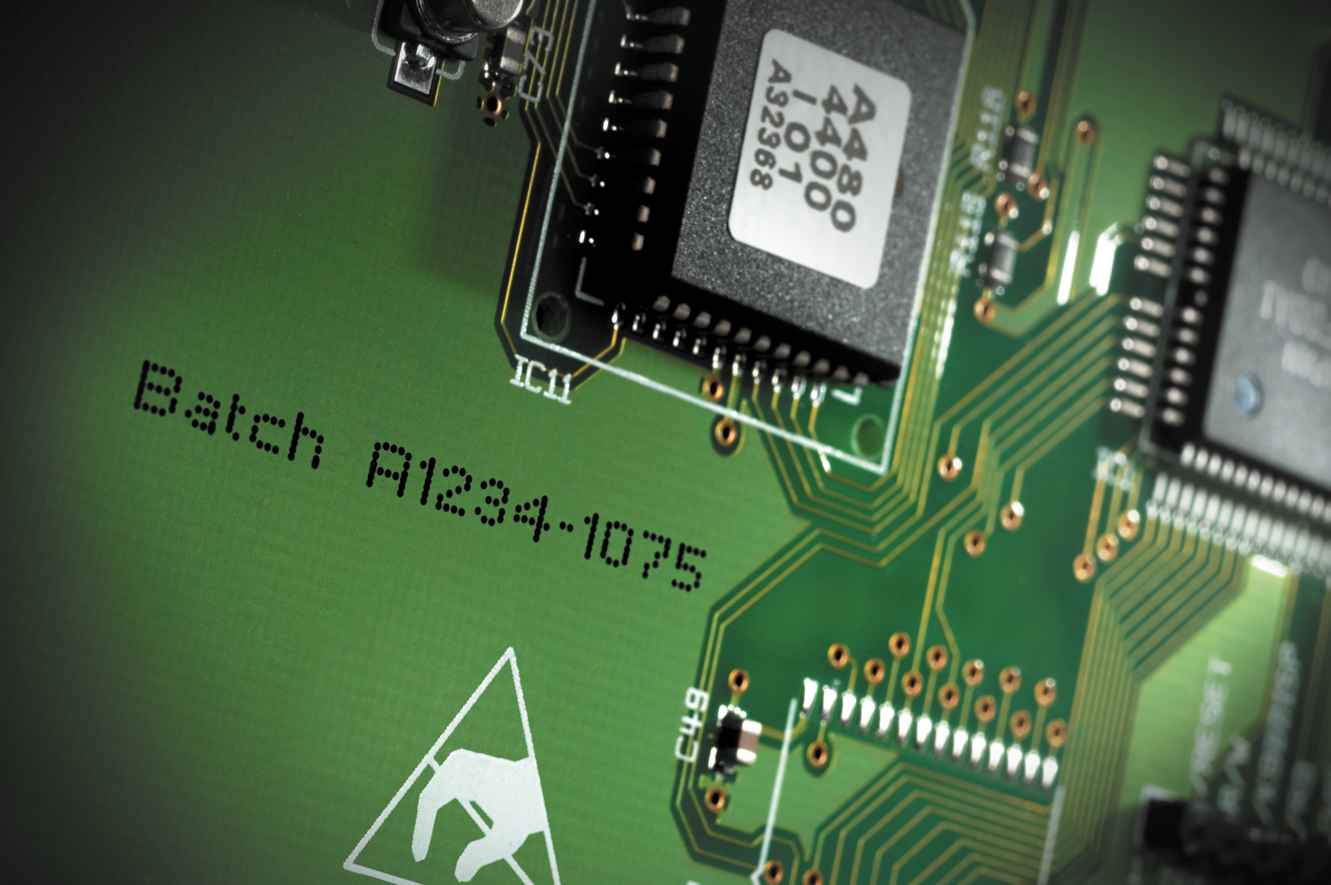

The electronics industry is involved in the manufacture of complex and delicate circuit boards, electronic components and wires, each requiring specialist marking and coding solutions. Even the smallest electronic components need legible coding for robust traceability and component identification: from microchips and capacitors to circuit boards, housings and much more.

With Linx coders, you can achieve permanent and temporary marking with solutions designed specifically for the electronics industry. In every case, Linx offers a range of benefits including in reduced downtime and increased efficiency on the production line.

Benefits of Linx Electronics Marking Solutions

- Designed for small spaces and small print, coding lines as small as 0.8mm

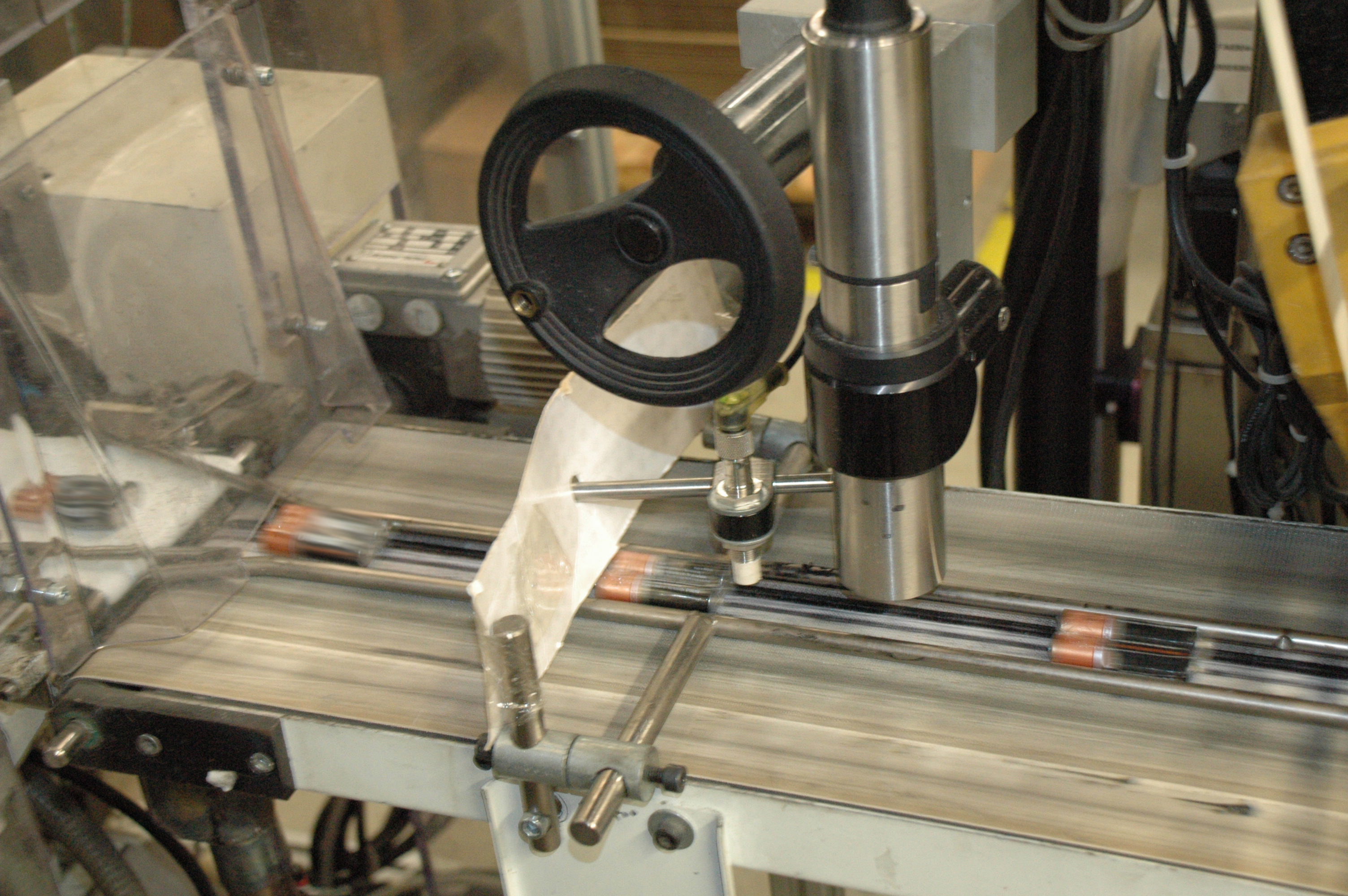

- Ideal for operation in fast production lines while ensuring product integrity

- Easy integration with your production lines using right-angle printheads

- Resist contaminants of dust, water, sugar etc, with IP-rated outer casings and easy-clean printheads

- Utilize water-soluble and pigmented inks for circuit boards, components, etc

- Remain cost-effective with 24/7 uptime in extreme production environments

- Consistently clear, high-quality marks & codes

Printer Types for Electronic Marking

Laser Coder

Printing lines as small as 0.8mm, Linx laser printers offer a permanent marking solution for rapid production lines. Added benefits include low maintenance and consumable costs.

- Easy setup, with touchscreen message management

- Laser tube lifespan estimated at 45,000 hours

- Multiple beams allow for coding at any orientation

Fibre Laser Printer

Fibre laser solution, with fine detail marking ideal for very small components. Built for reliability, the FSL laser printer integrates with nearly any production line, packed with features to guarantee longevity.

- Well-suited to medical, automotive and electronics sectors

- Able to print very small characters 0.1mm high characters

- Able to mark static

Continuous inkjet (CIJ) Printers

For lines as small as 1.4mm, Linx CIJ solutions produce high-quality temporary codes compatible with most substrates, with specialist manufacturing inks tailored to electronics and components.

- Easy changeover with messaging

- Suitable for short runs for batch coding

- Easy changeover with messaging

Our Laser machines can mark very small characters from 0.1mm height to very large text.

Yes, our machines can come with a stand to wheel on and off your production line when needed. Get in touch with us to get more information.

Yes. We can send data sheets to you upon request.

Our sales managers are more than happy to come and visit your site to see what machine will be best for your application. Get in contact with us here for more information and support.

Working with Linx

Want to know what is the best coding and marking solution for the automotive industry?

Call us, chat to us or simply fill in the form with your details and we will get back to you. Tell us what the main priorities in your production process are and we will help you choose the best solution tailored to your needs. And we will tell you how much you will save too!

Electronic Part Marking Capabilities

Linx Laser Coders and Continuous Ink Jet Printers (CIJ) are two popular and powerful solutions enabling product identification, branding and traceability across a huge range of components, in complete accordance with legislative compliance and common production processes.

Common applications:

- PCBs and circuit boards

- Flexible and integrated circuits

- Cable and wiring

- Electrical connectors

- Circuit breakers

- Small batteries

- Junction boxes

- Motors

- Switches

- Microelectronics

Linx capabilities include:

- Small and constrained production lines

- Clean and durable complex codes

- Simple self-service capability

- Intuitive touchscreen control

- 2D Data Matrix, barcodes, logos & traceability

- Compatibility with production processes

… and more. Contact us now for further information.

Related

Resources

Process Specific Inks Datasheet