Our Technology Guide for CIJ Printers

Continuous inkjets are perfectly suited for printing a wide range of information onto products and packaging on production lines. They are designed for automatic printing of batch codes, dates, barcodes, number sequences, general text, and even brand & product names.

Manufacturers and packing operations often use them for reliable traceability and in specific industries, compliance with legislative requirements. Linx continuous inkjet printers are renowned worldwide for ease of use, reliability, low running costs and the ability to mark materials of nearly any texture, shape, size or porosity.

How does a continuous inkjet work?

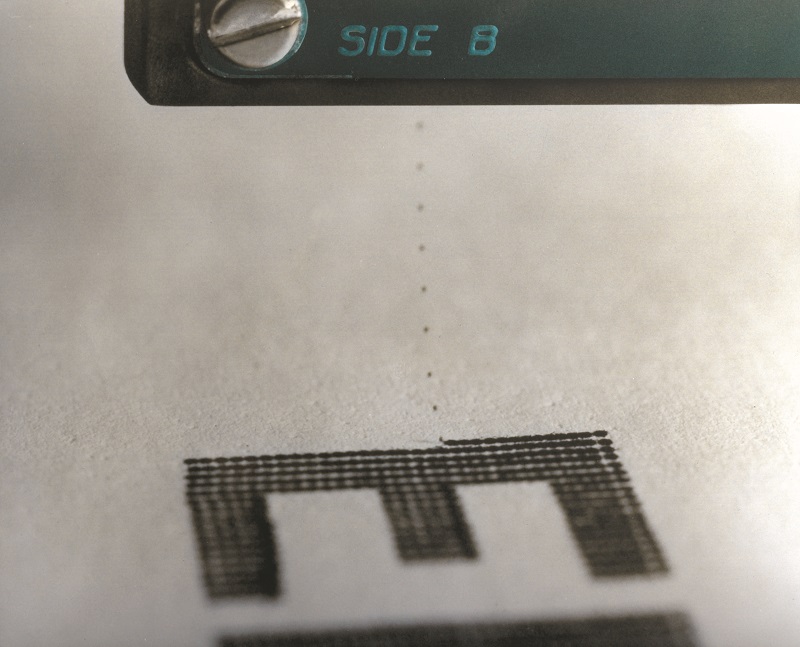

The continuous inkjet printing process works by expelling electrically charged ink droplets from a printhead nozzle and passing them through an electric field.

The ink jet is broken into drops inside the chamber through a pulse from the piezoelectric crystal. Droplets that are required for printing are charged by an electrode as they break off from the ink jet, and the printer re-circulates the rest.

The droplets, now charged, pass through an electrostatic field between deflector plates, a combination of speed and charge determines the correct position of the droplet on the substrate.

Up to 80,000 of these tiny droplets – half the diameter of a human hair – are expelled every second, and this is done without contact to the material being printed on.

Compare Linx CIJ Printers

Coding and marking solutions for a range of materials and environments

Inkjet Coding Applications

Our products are used in manufacturing worldwide, browse by industry or material

Remote Printer Management

Mobile monitoring and remote control of your production line printers