CHOOSING THE BEST DAIRY BATCH PRINTING SOLUTION

Quick links:

Introduction

The outlook for the dairy sector is positive, particularly as incomes rise and nations become increasingly urbanised, meaning individuals tend to receive more of their calories from proteins (which includes dairy) rather than carbohydrates (such as grains). This factor means global demand for dairy is expected to continue to grow1, also driven by rising incomes in emerging markets, for example the growing popularity of dairy products and cheeses in Asia.

Health and nutrition are also contributing to dairy’s growth. Some dairy companies are starting to use sustainable nutrition (healthy food that has been produced in an environmentally friendly way) in line with the UN’s 2030 Sustainable Development Goals. As part of this there is a significant trend, particularly among millennials, to seek natural foods such as probiotics.

There are other market trends to which the dairy industry is responding, for example the move towards smaller portion sizes, both to counter the problem of food waste as well as rising levels of obesity. On-the-go consumption is also growing, as is the demand for convenience solutions.

The development of new products leads to new packaging formats. Convenience examples include re-closable stand-up pouches for grated cheese; a four pack of 4oz yoghurt pots meets the need both for smaller packs and a ‘grab and go’ solution; a ¾oz cheese stick offers the benefits of a healthy snack at just 70 calories per portion.

New pack formats provide opportunities for range extensions, such as yoghurt and dairy drinks in pouches and PET bottles.3 Packaging also continues to play a vital role in brand image and on-shelf appeal in terms of design and decoration.

Another trend is a rapidly growing move for greater transparency across food chains, and consumer access to information about the companies they buy from, such as nutritional information and where ingredients were sourced. Technology developments have made it easier for organisations to improve their supply chain traceability, logistical efficiency, and visibility of supply chain risks.

The customer experience is important, including making it as easy as possible for consumers to find the information they are looking for, such as nutritional details and ingredients.

There are new value drivers for consumers when making food choices, with purchase decisions increasingly based on ‘product plus’ factors such as specific ingredients, how and where the product was made, and corporate values of the manufacturer and retailer. Firms must be able to communicate this holistic approach to consumers and provide them with relevant information in an open and transparent manner.

All of these developments underline the importance of consumer confidence in a company and its brand.

The role of the printed code in dairy packaging

Packaging can help to establish and maintain this consumer confidence, through the quality of the pack, the image it portrays and its functionality. In this scenario, the provision of printed variable information on dairy packaging may seem relatively minor and driven largely by legislation, national and international standards and accreditations. Many of the world’s largest food retailers are mandating supplier certification to global Food Safety Initiative (gFSI) schemes, which include SQF, BRC, IFS, FSSC, GLOBALG.A.P. and BAP and Canada GAP, alongside their own stringent specifications.

Nevertheless, although printed codes are a necessity, how they are produced and presented can have a significant impact on a business:

Improved brand protection and compliance in the dairy industry

High resolution, long-lasting quality printed or marked codes for use-by dates, batch or traceability data will ensure that dairy products meet all the necessary legislation and customer requirements. They will also complement the packaging, making sure the codes do not detract from its overall appearance.

The choice of equipment available means it is possible to select a solution for the many different packaging materials and substrates used for dairy packs. Another way of reducing errors, including inadvertent tampering, is to transfer messages between machines via USB, with different users assigned different levels of permission to create, select or change messages.

Code Quality

Printing and marking equipment that is reliable and easy to set up and use will contribute to an efficient operation.

Errors can be costly, for example lost time, lost product, the need for reworks and the possibility of a product recall and retailer fine. This can be particularly critical in the dairy sector with many perishable and short shelf-life products.

Modern printers offer simple message creation and editing with touch screen user interfaces, often using picture-led prompts, and on-screen help. This ensures consistency and reduces the likelihood of mistakes and reworks on the factory floor.

Improve dairy manufacturing productivity

Printing and marking systems can help to minimise product waste and increase manufacturing uptime in several ways:

Reducing stoppages

Machines that are easy to integrate into production lines mean less downtime during the installation process. For cold, chilled, damp or humid environments typically found in many dairy facilities, selection of a printer with the appropriate IP rating will avoid failures caused by ingress of solids or fluids into the machine. Self-cleaning printheads reduce blocked nozzles, while timely and visible notifications of low fluid levels allow refills to be scheduled into planned production line stops.

Planned stoppages can also be minimised through the use of printers with longer service intervals, and self-servicing and self-maintenance functions. Machines designed for use in washdown environments save time covering or removing them for cleaning.

Reducing waiting time

For dairy manufacturers needing frequent or fast product changeovers, then digital printing technology allows multiple messages to be stored. Messages can then be switched at the press of a button, reducing the time spent setting up new information compared to changing rollers or plates on non-digital machines.

Multiple line settings as well as data held in the printer’s memory mean information specific to product lines can be set up and indexed in the machine, making for quick product changeovers.

Lightweight machines can be moved between lines and set up quickly, making them more flexible in their use.

Reducing waste

Printing and marking systems that combine quality and accuracy will help to minimise waste by ensuring the correct information is printed every time, that it is legible and in the right place on the product. This is increasingly important where the amount of space available for functional information may be decreasing, particularly with the advent of smaller pack sizes. Set against this may be a legislative requirement on food products for the code to be printed using characters of a certain size. This requires printers that are able to deliver the code accurately into what may be a small area.

Reducing processes and over-production

Technology which requires minimal start-up procedures and where the first print is as good as the last means there is no need to leave machines switched on permanently, or to run them every day.

Machine versatility will enable manufacturers to use one model for several applications, printing onto a range of substrates. Less variation in machine types also leads to fewer instructions to learn and a reduced inventory of consumables.

Flexible printheads that can code in any direction, even from underneath the product or traverse across multiple lines, mean there is less product handling required to position it for printing.

Coder selection – factors to consider

Linx’s customer research has suggested that the key drivers for dairy printing and marking requirements are code accuracy and durability, along with ease of set-up and use.

As part of the selection process, the speed of the line and the substrates to be printed onto is critical. It is important to have each material type sample-printed to ensure legibility, particularly if a range of different colours is involved.

The majority of dairy code requirements are reasonably simple at present, but future food labelling legislation always has an element of uncertainty. Choosing a future-proof printer, which allows add-ons to be integrated at any time, will enable dairy manufacturers to react quickly to changing trends, customer demands or legislation without having to invest in new equipment.

The overall Cost of Ownership of any new machine purchase should be investigated. This takes into account both the initial price and factors such as reliability and the cost of consumables over the machine’s lifetime. Frequent breakdowns may negate any benefits of a lower purchase price. Leasing and rental options may also be worth exploring.

The different coding technologies

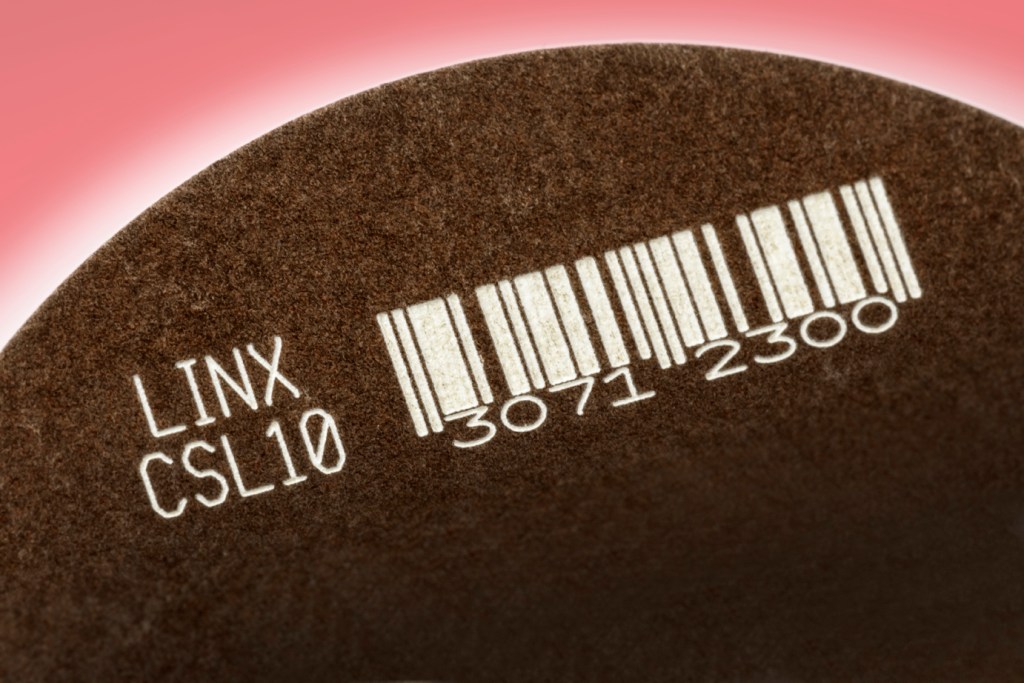

Continuous Ink Jet (CIJ)

CIJ can print on almost any substrate, and there are a wide range of inks available. These include inks of different colours to ensure legibility; food grade inks for applications where the code may come into contact with the product itself; fast-drying inks; and ones that ensure the codes do not rub off, even when there is moisture on the packaging.

CIJ can print from one to multiple lines of text and simple graphics on line speeds of up to 6.25m/s for a single line of code.

The compact printhead can be situated above, beside or beneath a production line or traverse from side to side across the line. With lighter models increasingly being produced, the CIJ printer is capable of being moved quickly from line to line and is fast to install and set up. The technology can provide the ideal solution to enable start-up and growing businesses to move from manual coding to digital printing methods in order to produce the type of quality codes demanded by the retail sector.

Large Character Marking (LCM)

Case coders are particularly well-suited for printing variable information onto secondary packaging such as cardboard boxes. These outer cases usually require larger text and graphics for visibility during shipping and storage.

Case coders can print to a high-resolution quality and are versatile enough for use on a variety of surfaces and materials. Benefits include ease of set-up and adjustment, reliability and predictable cost of ownership. They are also a cost-effective alternative to pre-printed boxes or labels.

Laser coders

Laser marking involves no ink in the coding process and therefore no drying time or risk of smudging. Laser coders are suitable for a wide range of substrates at any line speed. Benefits include increased uptime, higher speed capability and the fact there is no use of consumables.

Steered beam laser systems are highly versatile as they provide clear, consistent and perfectly formed characters in a variety of fonts and message formats, and enable the use of high quality graphics and logos over relatively large print areas.

They are particularly suitable where high quality codes are required, for example to blend in with the style of pre-printed packaging. Advances in technology and efficiency have led to a significant reduction in the initial purchase price. In addition, the low cost of ownership due to no consumables and relatively low maintenance mean laser coders are a viable choice for many dairy applications.

A new generation of lower cost compact laser marking solutions have also been introduced, which offer an affordable alternative to other technologies whilst still maximising functionality.

Conclusion

As with all purchasing decisions, in selecting a printing solution to suit their needs, dairy companies must carefully assess all the available options, with line speed, code content, the production environment and total cost of ownership important factors to take into consideration.

As consumer preference and new product development drive demand for new pack types, the ability of the printer to deliver clear, robust codes of varying complexity, at different points on the production line and onto the widest range of substrates, may provide a vital element of futureproofing.

Printers specifically developed for the demands of the dairy industry, with washdown capability and traversing printhead functionality, can help deliver the reliability, versatility and production efficiencies needed in this varied industry. In this way, they will ensure that every code meets the necessary compliance with the right level of quality to help support that all-important brand reputation.