CODING SOLUTIONS FOR PERSONAL CARE PACKAGING

The Coding Needs of a Fast-Developing Sector

The personal care sector has seen a major leap in demand for products as a result of the global Coronavirus outbreak. Demand for certain products more than doubled initially, and demand for certain products is set to remain high as homes and businesses require increased hygiene. Outside of hygiene related product, demand for other personal care products is expected to return to levels seen before the recent COVID 19 situation, as lockdowns are eased.

Product development in the sector is highly innovative and as a result the packaging substrates used are varied – resulting in a mix of types of packaging ranging from cartons and glass to plastic containers and pouches.

Cost can be an influencing factor – personal care products vary from the more basic economy to high-end luxury ranges, and the huge variety of packaging formats reflects the choice available to consumers.

In a crowded and competitive market, manufacturers are also looking for USPs to make their products stand out – bespoke container designs, niche vintage branding and enhanced decoration are examples of elements used in packaging to help achieve product differentiation on shelf.

Environmental considerations are now playing a prominent part in the personal care sector with brand owners reacting to a consumer requirement for environmentally friendly products and packaging by using more natural ingredients and recycled packaging.

Other influencing factors are urbanisation, an expansion of the middle classes, an increased beauty sophistication, especially within age ranges, and the growing popularity of male grooming. An ageing population is also affecting product functionality, and packaging therefore has to be practical, such as the use of easy-grip containers.

Size polarisation is another trend with consumers opting for both smaller formats and larger pack sizes. Smaller sizes are easier for consumers to travel with or test a product before buying a larger pack; oversized formats of beauty and personal care products are popular for daily use items such as shampoos and conditioners where consumers can get greater value for money by buying in bulk.

With so many different pack formats and materials, finding the best and most appropriate coding solution can be a challenge.

Coding – A Necessity or an Added-Value Operation?

Cosmetic, toiletry and perfumery products are subject to European laws and require certain information to be printed or labelled on packaging as well as an ingredient list. Regulation 1223/2009, which came into effect 11 July 2013, enables free movement of cosmetic products in the EU if the regulation is complied with.

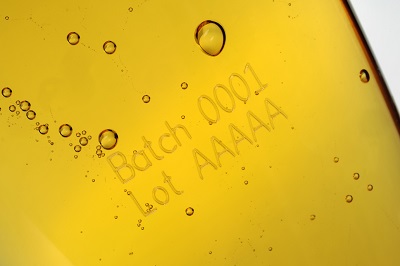

While much of the information required for personal care products, such as ingredients, will be pre-printed there is still the need for variable information. Lot codes and batch numbers help deliver effective traceability, often required by retailers and an important part of Good Manufacturing Practice (GMP). Some products may need a ‘period after opening’ or Best Before Date to show how long they may be safely kept. Coding can also offer anti-counterfeiting measures to form an important part of a brand protection strategy.

As coding is a necessity for the personal care sector, it is not usually perceived as adding value to the manufacturing or packing process. However, careful selection of the right equipment can make an important contribution to maximising production, ensuring that the finished code meets all in-line requirements while also complementing the packaging it appears on.

Helping with new working conditions resulting from COVID 19

Coding equipment can also help producers to meet post-COVID 19 changes required for workforce safety. Capabilities that will help include alcohol resistant printers and inks, to withstand more frequent production line cleaning. Remote control and monitoring will help to reduce human interaction with equipment and assist with social distancing requirements. Printers with large, clear and responsive touch screens and simple user interfaces will help operators who are wearing gloves to make coding changes right first time.

The Requirements of the Personal Care Sector

Extensive research by Linx among our customer base has identified three key requirements for coding equipment for personal care applications:

Flexibility to change between product lines

With many companies producing a wide variety of products, lines need to be easily reconfigured for maximum versatility. Short lead times, especially in the contract sector, require fast set-up procedures.

Code Quality and Full Traceability

Consistently accurate and legible codes are needed for effective traceability, to meet internal and external quality standards, and to avoid the costs of recalls and reworking. In image-conscious markets, a poor quality code may have a negative impact on the pack and affect brand image.

Cost of personal care coding equipment

Coding equipment needs to demonstrate its value through consistently reliable operation that minimises downtime and maintains code quality.

Linx Coding Technologies

Linx offers a number of different coding technologies, each with its own particular strengths depending on the application.

Linx CIJ printers can print onto almost any substrate and are available with a choice of inks – including a variety of colours – to ensure excellent quality and legibility on many different pack types. They can produce from one to multiple lines of text, as well as simple graphics, at high speeds, while the printhead can be situated above, beside or beneath the production line, or transverse it from side to side.

Linx TIJ models are designed for slower production lines or where production is not 24/7, the high resolution codes deliver superb print quality, making them appropriate for premium packaging.

Linx Laser coders deliver precise and high-quality permanent codes and graphics, including machine readable codes such as QR and Data Matrix, on a wide range of substrates. They are especially suitable for high speed, high volume 24/7 lines.

Large Character Marking printers code onto secondary outer cases. Linx case coders are well suited for printing variable information including text and graphics. Large codes as well as high resolution graphics make Linx LCM coders a popular alternative to labels or pre-printed packaging.

Solutions to Match Your Needs

Flexibility for quick and easy changeovers

Linx coders are easy to use, making setup for new lines and changeovers quick and simple. They offer ease of integration and the ability to code in any orientation, and many have the versatility to be moved easily between lines.

The colour touch screens and on-screen prompts on Linx CIJ printers enable quick code selection and setup on the Linx 8900 series printers. Linx QuickSwitch® Plus on the Linx 7900 delivers fast automated setup.

The compact dimensions of the Linx 8900 allows it to be easily integrated into existing lines and has a 20mm high carton coding option for secondary coding.

CIJ can code in any orientation – upwards, for example on the underside of aerosols, downwards or sideways, without any impact on code quality.

The Linx Laser SL1 CO2 coder is one of the most compact one-box laser solutions on the market, weighing only 12.5kg, making it simple to position on the line and where space is constrained, coding in any orientation.

The new range of Linx Fibre laser models can code onto a wider range of materials including bare metal. They have one of the smallest supply units and marking heads, which enable easy integration into even the smallest of factory spaces and they can code in both static and moving environments.

Linx TJ models are simple to install straight out of the box without needing a service engineer or specialist tools. They can be easily moved between lines, and rapid adjustment brackets allow print positioning to be changed as required. They have the versatility to deliver high resolution codes onto both secondary and primary packaging.

The touch screen interface on the Linx TJ725 offers ease of use and simple, intuitive configuration for quick message creation and changeovers.

The Linx IJ355 and IJ375 LCM printers offer a cost-effective and more flexible alternative to pre-printed boxes and cases. In addition, accurate, direct coding reduces the risk of incorrectly applied labels, while codes and graphic designs are not restricted by label size. The printers also help manufacturers react quickly to sudden demands and changes to code content.

Code Quality and Full Traceability

All Linx models offer consistently high quality readable codes that maximise uptime and avoid the costs of recalls or reworking.

Linx’s expertise in ink development adds versatility to our CIJ range, enabling inks and printer models to be matched for optimum coding, be it onto plastic, glass, paper, metal or cardboard. Linx Black PE ink 1130, for example, has been specifically designed for coding onto a wide range of plastics used in personal care packaging, including HDPE.

Coloured or pigmented inks such as grey or blue stand out clearly on most pack colours. Pigmented inks are robust and resist removal during production or customer use.

Linx PrintSync® enables automatic print format selection, using the line speed to ensure the best possible print.

For high volume, dedicated lines, Linx laser models deliver efficient, precise and excellent quality permanent codes, which stay in place on all colours and types of materials. The quality of scribing laser technology means the codes complement and do not detract from the packaging of premium products. High quality text, logos, graphics and Data Matrix codes can all be delivered with a Linx laser.

Linx Fibre lasers can code directly onto bare metal, making them ideal for many personal care applications. The technology delivers a very fine laser beam to create extremely small yet legible codes. This enables the printers to produce large amounts of code in small areas, offering an alternative solution to labels.

The permanence of the laser code is also beneficial for anti-counterfeiting measures for high value products.

The high-resolution printing of the Linx TJ range delivers excellent code quality up to 600dpi. The Linx TJ725’s Active Cartridge Care System® stops the nozzle from drying out, ensuring consistent code quality from start-up. An anti-ink bleed feature and a wide choice of inks allows coding onto paper, card, coated cards, wood, plastics, metal and glass.

For high definition graphics and readable barcodes, the Linx IJ355 and IJ375 are an ideal alternative to drop on demand technologies. The patented ReFRESH® system of the Linx IJ355 and IJ375 maintains premium print quality and avoids wasted ink during printhead cleaning.

Costs of purchase and ownership

The initial purchase price is just one factor in assessing the value for money of each machine. Poor reliability can lead to expensive breakdowns and unplanned stoppages, so it is important to select a machine that can work reliably in the factory environment. Ongoing consumables and servicing costs also need to be taken into account when choosing a coder.

The renowned reliability of Linx coders maximise uptime and can make an important contribution to Overall Equipment Effectiveness (OEE).

Positive air options and the availability of IP55 and IP65 ratings on Linx CIJ models allow continual reliable coding in dusty areas or washdown environments.

Linx’s industry-leading sealed printheads can function reliably in both wet and dusty environments. Minimal printhead cleaning requirements – only every three months – further maximise uptime.

The self-service module on the Linx 8900 provides an engineer-free service that takes just 30 minutes. Only filters and used fluids are changed regularly to reduce cost and waste. Advanced ink system technology enables the Linx 8900 series printers to run for up to 18,000 hours or 24 months between services.

The range of reporting functions on the Linx 8900 offer valuable production line feedback to help companies identify ways to improve productivity. Features such as real-time printer output and a batch status screensaver can help keep you on target. In addition, reports can be downloaded via a USB for reporting and analysis, making the Linx 8900 a useful tool to help you achieve your OEE metrics.

Linx lasers offer cost-effective coding as they use no consumables and require no external factory air cooling systems. The coders use much less laser energy than other models in their class, extending laser tube to over 100,000 hours on the Fibre lasers to further reduce running costs.

The disposable cartridge with integral printhead on the Linx TJ range eliminates any need for printhead repairs or replacement; installing a new cartridge is a fast and simple process.

The Linx IJ355 and IJ375 feature a robust design, including a tough stainless steel nozzle guard which protects the printhead from potential damage caused by impact with boxes on the line, while allowing the printhead to be close enough to the pack to ensure superior print quality is maintained.

Coding for Today – and Tomorrow

There are many challenges involved in selecting an effective coding solution that is exactly right for your specific personal care application. Each technology has its advantages, so it is important to prioritise your requirements. Also consider future coding requirements. If these are likely to change, given the predicted growth in the personal care industry, then selecting a coder that can adapt to change is a smart investment.

It is therefore worth taking the time to consider all the options and talk to Linx experts for guidance through the pros and cons of the different technologies and the machines available.