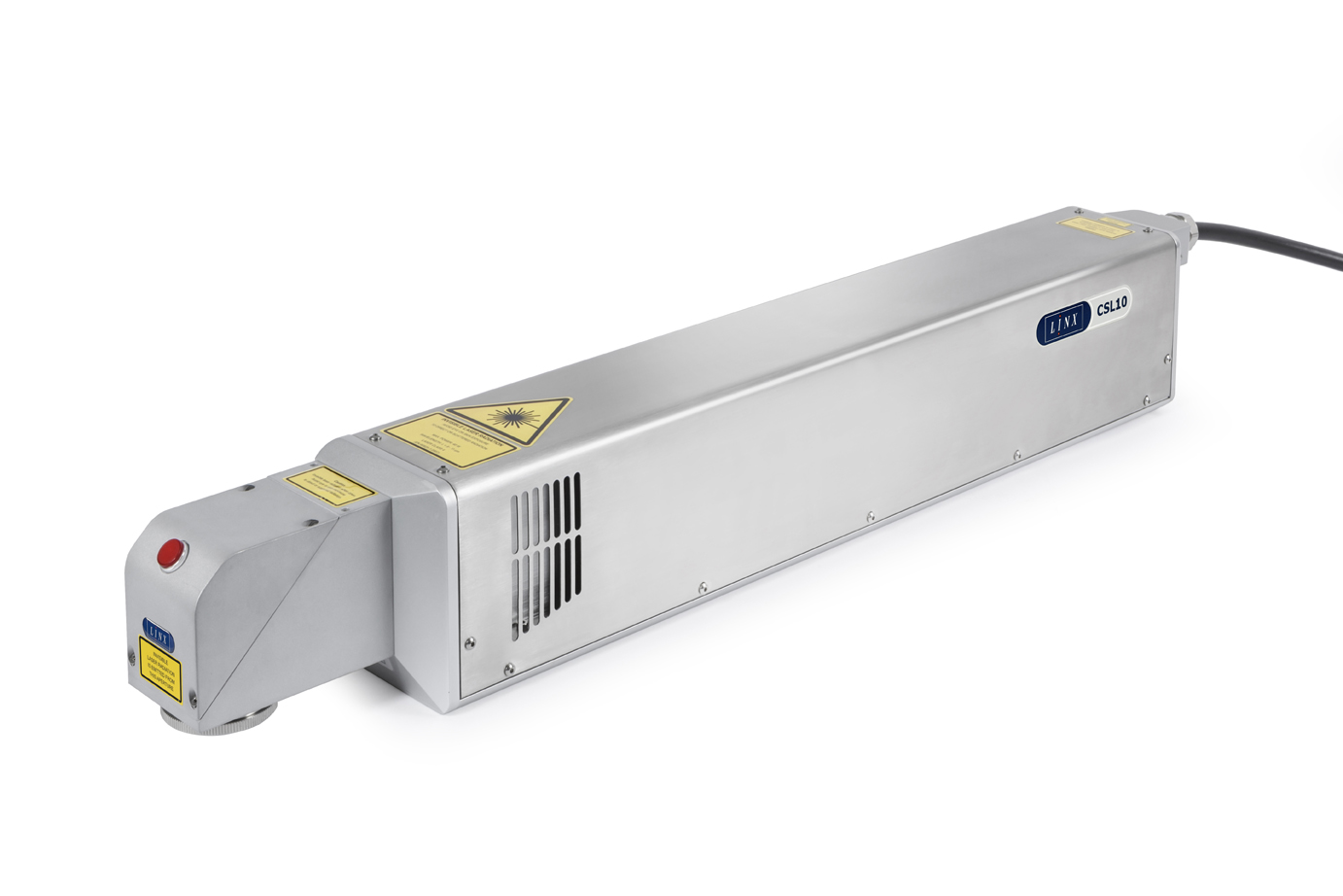

Linx SLHP

Superior quality codes at some of the fastest speeds available on the market.

The Linx SLHP is a high power, 120 W CO2 laser which can code accurately at high speeds – for example in excess of 70,000 bottles per hour on high speed beverage production lines. The high power allows many different materials to be marked quickly and permanently –including traditionally hard-to-mark substrates such as glass, rubber and PET.

Key benefits

- Graphics can be accurately reproduced with vector-generated codes

- High power of the laser means a shorter dwell time on the product

- Air-cooled – no factory air required

- Large scan area for multiple lines of code/graphics

- IP56 rating ensures reliable operation in harsh production environments

- Internal air cooling system for increased efficiency and less maintenance

- Air-cooled – no factory air or water required

- Efficient use of the laser source prolongs the life of the laser tube

- No ongoing consumable costs

Resources

SLHP Datasheet

Technical Specifications

Marking Formats

- High quality codes

- Large area marking capability

- Simple alphanumeric codes

- Multi-line codes

- GS1

- Bar codes

- 2D Data Matrix

- Accurate reproduction of complex graphics, logos, symbols

Applications

- Static and ‘on the fly’ coding

- High speed beverage lines on glass, plastic and labels

- High speed and complex pharmaceutical coding

- Anti-counterfeiting e.g automotive, high value perfumes/spirits, tobacco

- Wide range of materials including rubber, glass, PET, PVC

Software

- Comprehensive and versatile

- Multiple EU display languages included

- Time/date stamp

- Incremental fields

- Text orientation

- 3 level password protection

- 2 channel quad encoder input

- Flash memory backup

- RS232 interface

- Windows® operating system

Physical Characteristics

- Laser – single sealed CO2

- Average coding power – 120 watts

- Beam delivery – 7 knuckle articulated arm for optimal integration

- IP rating – IP56 marking head and supply unit

- Cooling – Integral air cooling; water cooled option for high duty applications

- Supply voltage – 200-240v 50/60 Hz Single or Bi-phase

- Integral QWERTY keypad; remote keypad option