Beverage Marking

We offer a full range of beverage marking printers designed to meet the challenges faced by the beverage industry every day. We code onto wet bottles without sacrificing high line speeds and robust traceability.

Whether you’re coding best by dates, manufacture dates, traceability codes, or anti-counterfeit marks we can meet your specific needs.

We offer many solutions ideal for printing onto plastic / glass bottles, bottle caps, cartons, aluminum cans and labels.

Quality beverage coding to protect your brand

- Permanent laser coding of complex logos, circular text and 2D codes directly onto bottles to prevent counterfeiting

- ‘Invisible’ UV-readable codes offer discreet coding for internal traceability as well as anti-counterfeiting

- White, yellow, grey, or light blue pigmented inks provide legible codes even on dark glass or PET

Reliable operation in challenging environments

- Protection against water infiltration during production or CiP processes - Linx 8900 Series ink jet printers and CSL laser coders both have stainless steel enclosures with IP55 rating as standard.

- With the Linx 8900 Series enjoy long service intervals of up to two years and minimal cleaning which means more uptime on busy 24/7 lines

Maximize productivity

- Code up to 70,000 bottles per hour on high-speed bottling lines

- Print both primary and secondary codes with the Linx 8900 Series – ideal for bottles/cans as well as outer cases

- Remotely monitor/manage your printers and predict end of batch runs with Linx PrinterNet.

Contact Us

Why not get in touch with one of our sales reps to talk about how Linx can support your coding and marking needs?

Beverage marking printers

Our coding experts can advise you on the best solution from our range of marking machines for the beverage industry. We can help you to reduce waste, maximise production throughput and meet deadlines.

Continuous Inkjet (CIJ) printers

Linx CIJ Printing solutions can help to maximize production time between multiple SKUs with quick, error-free code changeovers while line setups can be stored and retrieved for repeat work.

The Linx 8900 Series printers are designed to make operation and efficiency easier than ever and will support your business with:

- Meeting your output targets

- Reliable, continual operation

- Traceability of your products

- Meeting compliance requirements

- Remote printer monitoring and proactive support

Laser coders

Linx laser coders are suitable for a wide range of substrates and applications at high speeds even in wet and dusty environments. Benefits include increased uptime with minimum maintenance, high quality permanent codes and the fact there is no use of consumables.

Laser marking involves no ink in the coding process and therefore no drying time or risk of smudging.

Quality beverage coding across a range of packaging materials

Plastic, glass and paperboard

Mark batch numbers, expiry dates, 1D and 2D barcodes, logos, and lot information directly onto glass and plastic bottles.

Bottles, labels and sleeves

High quality, highly visible coding directly onto labels, sleeves, and paperboard with Linx CIJ and laser coding solutions.

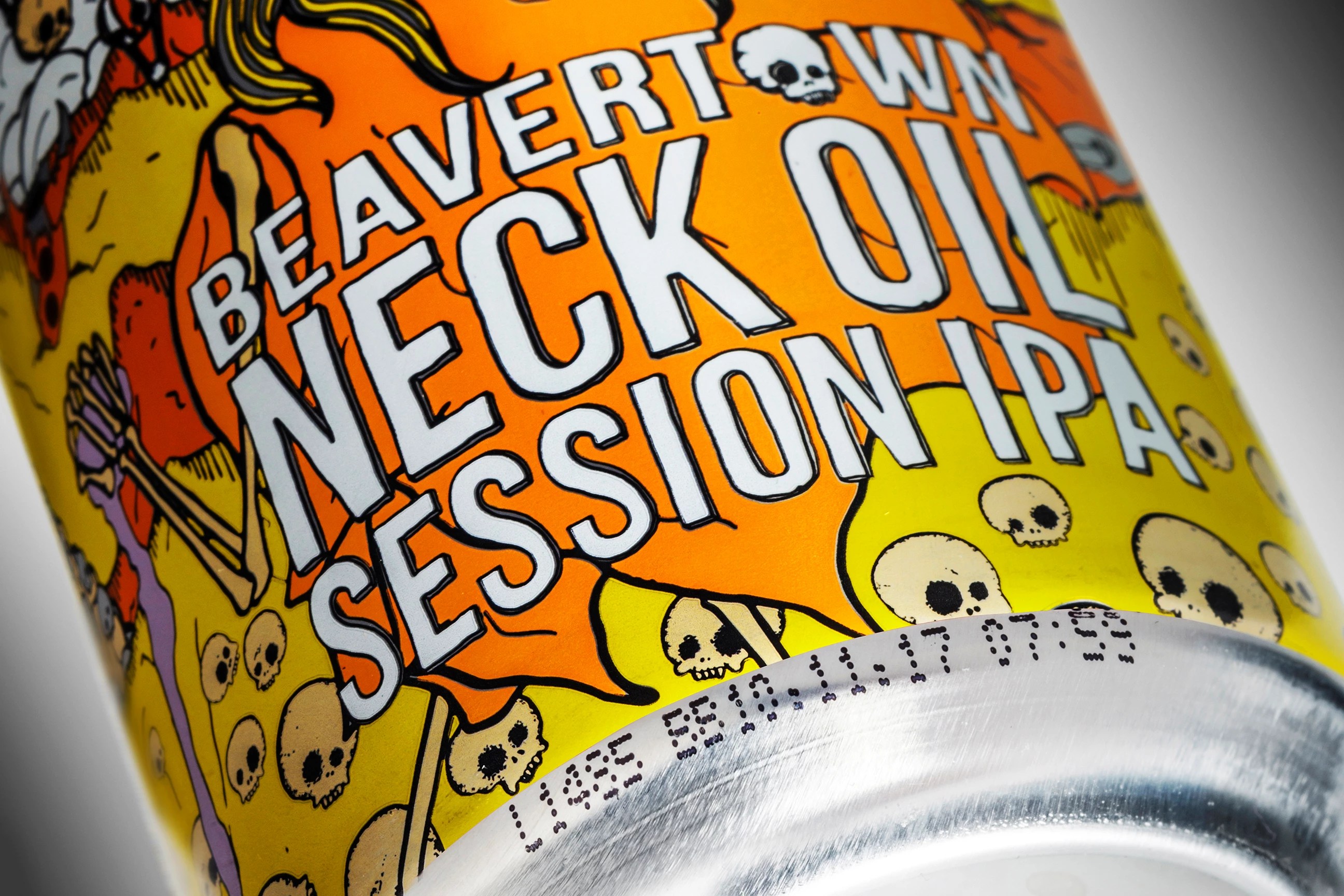

Aluminum and Metal Materials

Linx Continuous InkJet (CIJ) printers and laser coders offer reliable coding and marking on metal even in harsh manufacturing conditions.

Resources

Choosing the Best Beverage Coding Solution White Paper

Beavertown Brewery

Special Adherence Inks Datasheet

Bruichladdich Distillery Co. Ltd Case Study