CODING & MARKING SOLUTIONS FOR THE CHEMICAL MANUFACTURING INDUSTRY

Quick links:

The role of printed code in chemicals packaging

Printer selection – factors to consider

The different coding technologies

Introduction

The chemical industry has seen a major leap in demand for products as a result of the global Coronavirus outbreak. Demand for certain products more than doubled initially, and demand for these is set to remain high as homes and businesses require increased hygiene for the foreseeable future. Outside of hygiene related product, demand for other packaged chemicals is expected to return to levels seen before the recent COVID 19 situation, as lockdowns are eased.

In an industry where margins are crucial, the overall cost of ownership of machinery such as coding and marking equipment can play an important role in reducing spend.

Overall Equipment Effectiveness (OEE) and the desire for cost saving are being used by many coding equipment vendors to reinforce the benefits of their products. The best modern printers are designed to maximise OEE and minimise scheduled maintenance time.

The role of printed code in chemicals packaging

The content of batch and traceability coding may vary across different sectors of the chemical industry. However the finished code must resist reasonable wear and tear – which is a given in any industry. The chemicals industry presents particular challenges in code durability due to the nature of the product being packaged. In order to reduce recalls or rejects, these challenges must be met if chemicals manufacturers are to remain competitive.

Batch coders provide many benefits to satisfy coding regulations and ensure OEE is maximised.

Helping with new working conditions resulting from COVID 19

Coding equipment can help producers to meet post-COVID 19 changes required for workforce safety. Capabilities that will help include alcohol resistant printers and inks, to withstand more frequent production line cleaning. Remote control and monitoring will help to reduce human interaction with equipment and assist with social distancing requirements. Printers with large, clear and responsive touch screens and simple user interfaces will help operators who are wearing gloves to make coding changes right first time.

Improved brand protection and compliance in the chemical industry

Use-by dates, batch and traceability printed codes that are high resolution and long-lasting, will ensure that chemical products satisfy necessary legislation and customer requirements, with clear and legible codes that stay in place on all types of packaging materials.

The wide choice of equipment and consumables means it is possible to select a solution for many different substrates such as metal cans, all types of rigid and flexible plastics including PET, PVC, HDPE, and PP, paper and cardboard.

Ink-based coders with specialist inks, and laser coders, can deliver chemical-resistant codes that stay put during both production and end-use by the customer. Other specialist inks are available that can print and adhere to packs that are covered with a light layer of oil or grease.

Whatever the printing requirements, errors can be costly in terms of lost time, lost product, the need for reworks and the possibility of a product recall. Modern printers offer simple message creation and editing with touch screen user interfaces, often using picture-led prompts, and on-screen help. This ensures consistency and reduces the likelihood of mistakes and reworks on the factory floor.

Another way of reducing errors, including inadvertent tampering, is to transfer messages between machines via USB, with different users assigned different levels of permission to create, select or change messages.

Similarly, automatic code selection is enabled where barcode scanners are linked to printing and marking equipment. Additional protection of message accuracy is delivered where individual or multiple printers can be managed and monitored from a central computer.

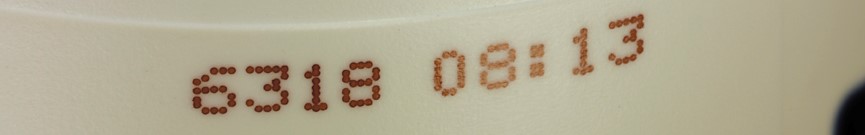

High-quality coding onto chemical products

A poor-quality code, which is either illegible against the substrate colour or smudged, can also result in costly rework or scrappage. Digital CIJ and laser coding systems deliver many different code sizes and styles, including 2D QR codes, onto most materials with clear and legible printing. Non-contact printing methods enable variable data to be printed onto a range of container shapes such as rounded tins or the base of aerosol cans, while maintaining consistent print clarity. Pigmented inks in various colours will ensure codes stand out against different coloured substrates.

Robust and reliable printers will be able to operate consistently even in 24/7 production environments. Printers with IP55 or IP65-rated steel enclosures, or a sealed printhead, offer protection against liquid or particle contamination, and can operate in dusty or wet environments, to prevent unplanned stoppages and ensure high quality continuous coding. Tough yet flexible printhead conduits can cope with repetitive actions such as traversing applications, and contribute towards continual operation.

Quality machines will also offer greater functionality, helping to reduce costs while maximising efficiencies. For example, printers with a carton coding feature have the flexibility to code both primary and secondary packaging with a single machine.

Improve chemical manufacturing productivity

Printing and marking systems can help to minimise product waste and increase manufacturing uptime in several ways:

Increased Speed and Flexibility – traversing printheads are able to print across multiple products at high speeds. This is particularly useful for high volume lines. Versatile printers that can handle a variety of requirements, including multiple lines of text, and human- and machine-readable codes, will enable manufacturers to meet differing standards or regulations. This will help companies satisfy export market requirements for particular countries, and also provides a valuable element of future-proofing.

Reducing stoppages – features such as self-cleaning printheads will reduce blocked nozzles and maximise printer uptime, while timely and visible notifications of low fluid levels allow refills to be scheduled into planned production line stops.

Planned stoppages can also be minimised through the use of printers with longer service intervals, and self-servicing and self-maintenance functions.

Reducing waiting time for manufacturers needing regular product changeovers, digital printing and marking technology allows multiple messages to be stored. These can then be switched at the press of a button, reducing the time spent setting up new information, compared to changing rollers or plates on non-digital machines.

Multiple line settings as well as data held in the printer’s memory mean information specific to product lines can be set up and indexed in the machine, making for quick product changeovers.

Lightweight machines that can be moved between lines and set up quickly reduce set-up time and downtime between production runs. They also allow producers to react quickly to changes in customer orders and to be more flexible in their operations.

Reducing waste – printing and marking systems which are able to apply the correct information in the right place on the product will help to minimise waste by reducing the amount of rework for incorrect codes, scrappage for products which cannot be re-coded as well as the extra time needed for reworking. This is increasingly important where the amount of space available for functional information may be limited, which requires printers that are able to deliver the code accurately into a small area.

Reducing processes and over-production – technology which requires minimal start-up procedures and where the first print is as good as the last means there is no need to leave machines switched on permanently, or to run them every day.

Machine versatility, such as the ability to print multiple lines of variable information as well as logos and carton coding all with one printer, will enable manufacturers to use a single model for several applications, printing onto a range of substrates. Less variation in machine types also leads to fewer instructions to learn and a reduced inventory of consumables.

Printer selection – factors to consider

Linx’s own Voice of Customer research suggests that the key drivers behind printer purchases in the chemical manufacturing industry include flexibility of operation, where printers can code onto a range of materials and colours. The quality of the finished code is also important in order to meet customer and regulatory requirements. In addition, controlling costs from unnecessary downtime and missed production targets can be supported by a robust, reliable coding solution, which is simple to use and which saves time when setting up and operating.

As part of the selection process, the speed of the line and the materials to be printed are critical. It is important to have each material type sample-printed to ensure legibility, particularly if a range of different colours is involved. Consider also a trial of a printer on the production line, so that it is exposed to your specific production environment and processes.

The overall Cost of Ownership of any new machine purchase should be investigated. This takes into account both the initial price and factors such as reliability and the cost of consumables over the machine’s lifetime. Frequent breakdowns can negate any benefits of a lower purchase price. Leasing and rental options may also be worth exploring.

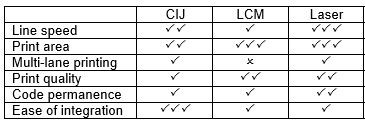

The different coding technologies

Continuous Ink Jet (CIJ) – as a non-contact printing technology, CIJ has the ability to print onto almost any type or shape of material. A wide range of inks is available, including pigmented inks of different colours, fast-drying inks, and UV cure inks, which provide excellent adhesion, light fastness and resistance to a range of chemicals packaging. These are ideal for preventing code transference during production or during end-use when accidental contact with a container’s contents could cause smudging or code removal.

CIJ can print from one to multiple lines of text and simple graphics on line speeds of over 7m/s for a single line of code. The compact printhead can be situated above, beside or beneath a production line or traverse from side to side across the line. With lighter models increasingly being produced, the CIJ printer is more capable of being quickly moved from line to line and is fast to install and set up. The technology can provide the ideal solution to enable start-up and growing businesses to move from manual coding to digital printing methods in order to produce higher quality and greater consistency of codes.

Large Character Marking (LCM) – case coders are particularly well-suited for printing variable information onto secondary packaging such as cardboard boxes. These outer cases usually require text and graphics which are easy to see.

Case coders can print to a high-resolution quality, and are versatile enough for use on a variety of surfaces and materials. Benefits include ease of set-up and adjustment, reliability and predictable cost of ownership. They are a cost-effective alternative to pre-printed boxes or labels.

Laser coders – laser marking has no ink involved in the coding process and therefore no drying time or risk of smudging. Laser coders are suitable for a wide range of substrates and at high line speeds. Benefits include increased uptime, higher speed capability and the fact there is no use of consumables. Laser marking leaves a permanent code which on PVC produces a colour change for added code visibility.

Steered beam laser systems are highly versatile as they provide clear, consistent and perfectly formed characters in a variety of fonts and message formats, and enable the use of high quality graphics and logos over relatively large print areas.

Laser coders can also cover a large print area and on high line speeds. This makes them suitable for multi-lane printing onto multiple products in one pass, without the need for a Advances in technology and efficiency have led to a significant reduction in the initial purchase price, and laser coders deliver low cost of ownership due to no consumables and relatively low maintenance.

A new generation of cost-effective compact laser marking solutions have also been introduced, which offer an affordable alternative to other technologies while still maximising functionality. mechanical moving printhead.

Conclusion

In an industry which can require information to be printed onto containers at various stages of the process, at varying speeds or angles and in different environments, coding and marking equipment must be able to meet complex demands comfortably.

Robust coders are required to operate reliably in challenging production environments, with trouble-free integration into production processes: ready to code onto most packaging shapes and materials, and meet the changing demands placed on the production lines.

Long service intervals on printers, where only minimal parts need to be changed and other components are designed to be fit-for-life, make scheduled maintenance quicker and less costly.

Selecting coders that are reliable, with minimum service or maintenance requirements and ease of use to aid quick operation and minimise errors, can help maximise OEE. As well as facilitating smooth manufacturing processes, this will also help companies deliver a top-quality service to their customers.