Huhtamaki

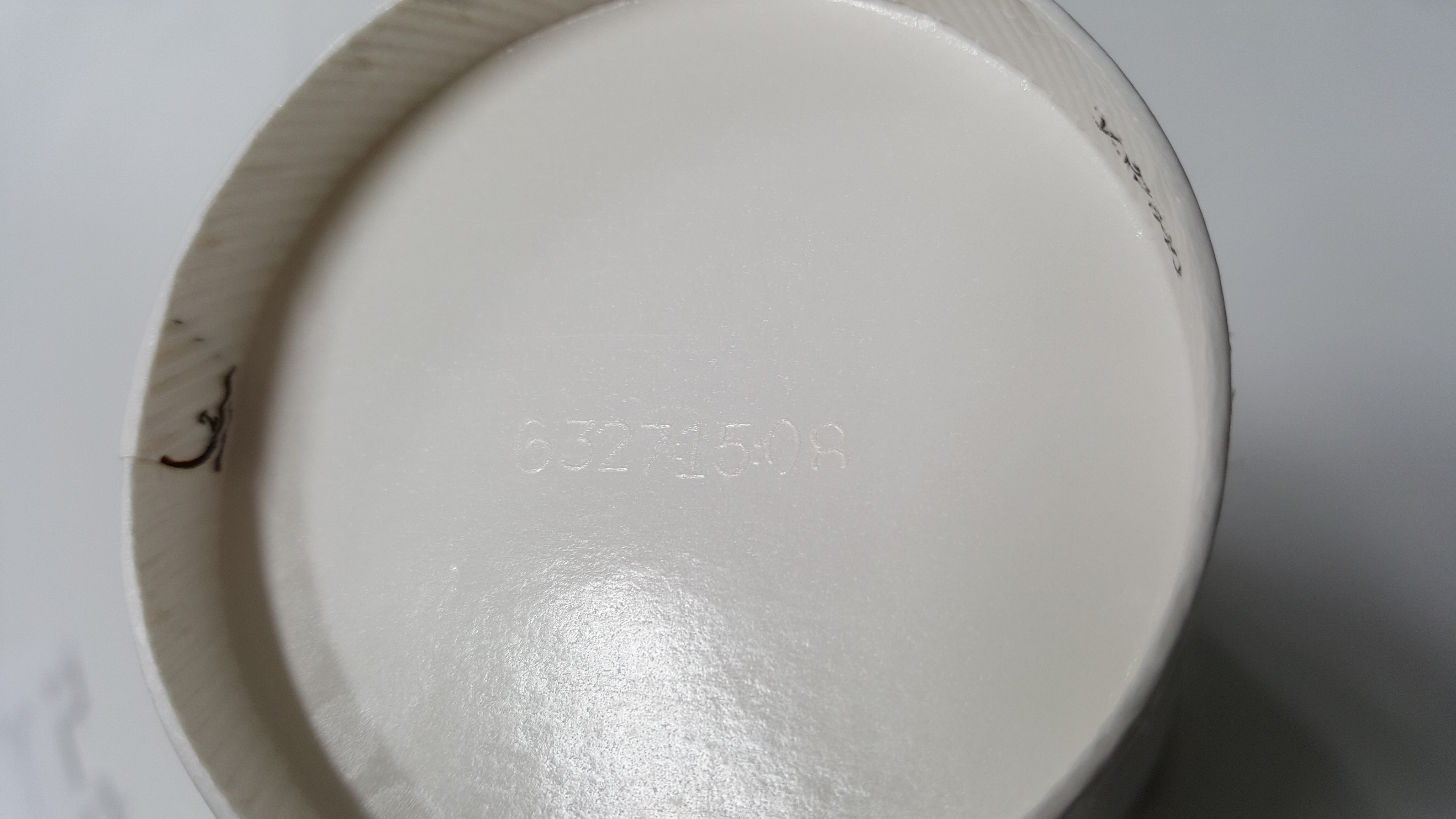

Huhtamaki has installed a Linx laser coder for applying permanent codes onto paper cups.

Huhtamaki is a global leader in packaging technology, and New Zealand’s leading manufacturer of food service packaging. When Huhtamaki decided to upgrade their product traceability solution they turned to Linx distributor Reynolds.

Previously Huhtamaki used inkjet technology to code their hot fill paper cups for identification and quality purposes, but with the need to ensure a completely indelible code and with a focus on cleanliness and lowering operating costs the decision was made to move to laser coding.

The application was not an entirely easy one, says Engineering Manager Greg White. “We have multiple production lines based on differing converting machines, meaning each installation had its own engineering challenges. Speeds are high, space is tight, health & safety is critical, and production downtime is something we just cannot afford.”

After evaluating different vendors, Huhtamaki selected Reynolds and the Linx 10W laser coder. “We compared a number of potential vendors, and selected Reynolds based on their strong engineering capability and history of excellent post-sales service.” Says Greg.

Reynolds fitted five Linx 10W laser coders, integrated to the different packaging machines, complete with comprehensive safety interlocking and guarding. The Linx units are ideal due to their highly compact size, flexible configuration and excellent price to performance ratio.

Says Greg, “Some of the installs were very tricky, and it’s great to know we have a really capable partner like Reynolds. In fact, Reynolds has now implemented automated verification systems to ensure the correct packaging variants are being run on the lines. It’s a real advantage having one partner who can deal with all the traceability and verification systems.”